How does anaerobic digestion work?

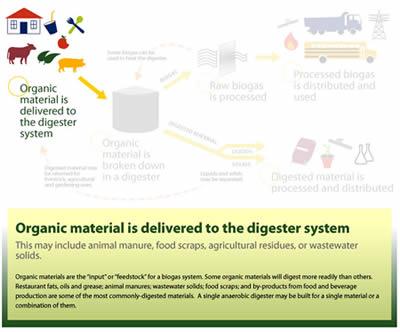

Anaerobic digestion is a process through which bacteria break down organic matter—such as manure—without oxygen. As the bacteria “work,” they generate biogas. The biogas that is generated is made mostly of methane, the primary component of natural gas. The non-methane components of the biogas are removed so the methane can be used as an energy source.

Some types of organic matter break down more easily than others. Generally, the more “digestible” the organic matter is, the more biogas can be produced. Codigestion occurs when anaerobic digestion is used to break down multiple types of organic waste in one anaerobic digester. Organic wastes that can be used in codigestion with manure include restaurant or cafeteria food wastes; food processing wastes or byproducts; fats, oil and grease from restaurant grease traps; energy crops; and crop residues. Codigestion can increase biogas production from low-yielding or difficult-to-digest organic waste.

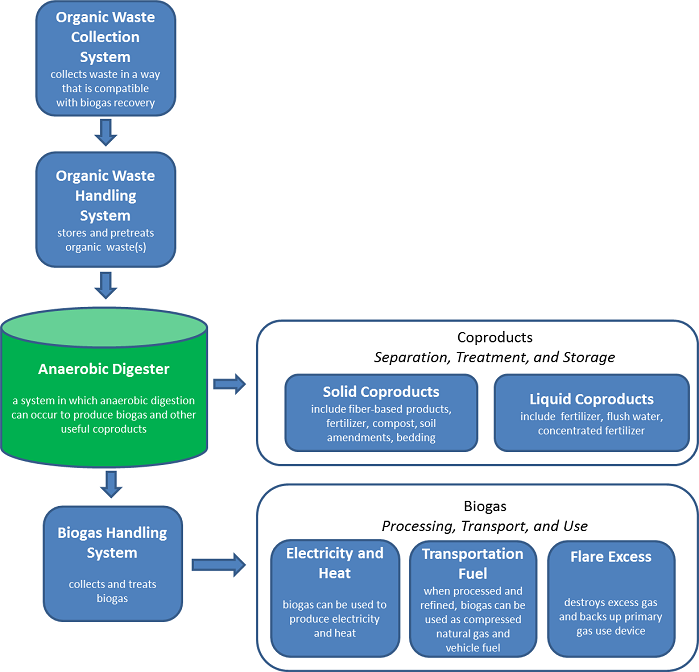

The following diagram illustrates the elements of a biogas recovery system. Details about each element are provided below the diagram.

Organic Waste Collection System

Biogas production is best suited for farms that collect manure:

- As a liquid, slurry or semi-solid;

- At a single point (a lagoon, pit, pond, tank or other similar structure);

- Every day or every other day;

- Free of large amounts of bedding or other materials (e.g., rocks, stones, straw or sand), which can clog the pipes of the digester and hinder operation.

Other materials such as feed additives with antibiotics and equipment cleaning and maintenance compounds (e.g., detergents, acids and halogens, etc.) may be harmful to anaerobic bacterial action. The typical use of these materials has not been a problem in full scale digesters. However, threshold levels for these compounds have not been established, so operators should be careful not to release large quantities of these materials into manure before it is fed to the digester.

Chain drag scrape alley; Credit: AgSTAR

Chain drag scrape alley; Credit: AgSTAR

Receiving pit for flush dairy dry lot; Credit: AgSTAR

Receiving pit for flush dairy dry lot; Credit: AgSTAR

Sand bedding: Credit: McLanahan Corporation

Sand bedding: Credit: McLanahan Corporation

Organic Waste Handling System

Manure may be pre-treated before entering a digester to adjust the total solids content. This may include adding water, separating solids, mixing or heating.

Anaerobic Digester Designs

Covered Lagoon

In a covered anaerobic lagoon design, methane is recovered and piped to the combustion device from a lagoon with a flexible cover. Some systems use a single cell for combined digestion and storage.

Diagram of a covered anaerobic lagoon showing 2 cells, where the first cell collects the digester influent and traps the biogas and the second cell collects the digester effluent

Diagram of a covered anaerobic lagoon showing 2 cells, where the first cell collects the digester influent and traps the biogas and the second cell collects the digester effluent

Photo of a covered anaerobic lagoon

Photo of a covered anaerobic lagoon

Plug Flow

Plug flow digesters are primarily used at dairy operations that collect manure by scraping. Mixed plug flow systems have been used at a wider variety of operations because they can tolerate a broader range of solids concentrations.

Diagram of a plug flow digester showing digester influent entering and flowing through the digester with the biogas being captured and stored beneath a cover

Diagram of a plug flow digester showing digester influent entering and flowing through the digester with the biogas being captured and stored beneath a cover

Plug flow digester with a flexible cover

Plug flow digester with a flexible cover

Plug flow digester with a rigid cover

Plug flow digester with a rigid cover

Complete Mix

Complete mix digesters are designed with an enclosed, heated tank with a mechanical, hydraulic or gas mixing system. Complete mix digesters work best when there is some dilution of the excreted manure with water (e.g., milking center wastewater).

Diagram of a complete mix digester illustrating the process of adding manure into the digester; mixing, heating and storing the biogas within the digester; and extracting the resulting effluent

Diagram of a complete mix digester illustrating the process of adding manure into the digester; mixing, heating and storing the biogas within the digester; and extracting the resulting effluent

Photo of two complete mix digester tanks

Photo of two complete mix digester tanks

Photo of an externally mounted mixer

Photo of an externally mounted mixer

Other Designs

Other common designs for anaerobic digesters include:

- A batch digester is the simplest form of digestion, where manure is added to the reactor at the beginning of the process in a batch and the reactor remains closed for the duration of the process.

- Induced Blanket Reactors are digesters in which a blanket of sludge develops and retains anaerobic bacteria, providing a bacteria-rich environment through which the feedstock must pass.

- Fixed film digesters contain plastic media (e.g., pellets) on which bacteria attach and grow, instead of relying solely on suspended bacteria to break down the digester feedstock.

Coproducts: Solid and Liquid Components

Digested solids can be removed from the digester effluent with a solids separator. Solids are commonly used as livestock bedding, but can also be sold for use in landscape products, such as soil amendments or biodegradable planting pots. Emerging applications for effluent solids include use in structural building materials, such as deck boards and particle board.

Photo of a screw press separator

Photo of a screw press separator

Photo of separated solids conveyed from screw press separator

Photo of separated solids conveyed from screw press separator

Photo of potting mix created from digested solids

Photo of potting mix created from digested solids

Photo of cows on separated solids bedding

Photo of cows on separated solids bedding

Photo of packaged potting mix from digested solids

Photo of packaged potting mix from digested solids

Photo of planting pots made from digested solids

Photo of planting pots made from digested solids

The liquid effluent from a digester can be used as a fertilizer, reducing the purchase of commercial fertilizers.

Photo of a crop irrigation system

Photo of a crop irrigation system

Biogas Handling System

Photo of a biogas treatment system for a pipeline gas project

Photo of a biogas treatment system for a pipeline gas project

Captured biogas is transported through a pipe from the digester, directly to a gas use device or to a gas treatment system. In most cases, the only treatment needed is to remove excess moisture prior to combustion. However, if the feedstock contains high concentrations of sulfur, then hydrogen sulfide is removed from the gas to prevent corrosion of the combustion device.

Biogas: Processing, Transport, and Use

Electricity and Heat

While a variety of biogas use options are available, the collected biogas is most often used to generate electricity.

Photo of a 120 kW engine generator set combusts recovered biogas, generating electricity for on-farm use

Photo of a 120 kW engine generator set combusts recovered biogas, generating electricity for on-farm use

Thermal energy in the form of waste heat, produced during electricity generation, can be recovered to heat digesters or adjacent buildings.

Photo of a heat exchanger that works in conjunction with an engine-generator set to recover heat for space and water heating, thus reducing fuel oil or propane costs.

Photo of a heat exchanger that works in conjunction with an engine-generator set to recover heat for space and water heating, thus reducing fuel oil or propane costs.

Biogas can be fired directly in boilers or heaters as a replacement for propane.

Photo of biogas boiler. Biogas can be fired directly in boilers or heaters as a replacement for propane

Photo of biogas boiler. Biogas can be fired directly in boilers or heaters as a replacement for propane

Transportation Fuel

Biogas can be processed to pipeline quality and sold to the local gas utility.

Photo of a biogas pipeline

Photo of a biogas pipeline

Biogas can be converted to compressed natural gas (CNG) which can be used in applications such as vehicle fuel.

Photo of a truck fueling with compressed natural gas

Photo of a truck fueling with compressed natural gas

Flare Excess

Flares are used to combust excess biogas or to combust biogas during periods when the primary gas use device is undergoing maintenance or repair. In cases where the primary purpose of the digester is to control odor or generate carbon credits, all of the biogas may be flared.

Photo of a biogas flare and flame.

Photo of a biogas flare and flame.

Photo of a biogas flare

Photo of a biogas flare

Learn More

Learn more from the following resources: