Stories of Progress in Achieving Healthy Waters

U.S. EPA Region 3 Water Protection Division

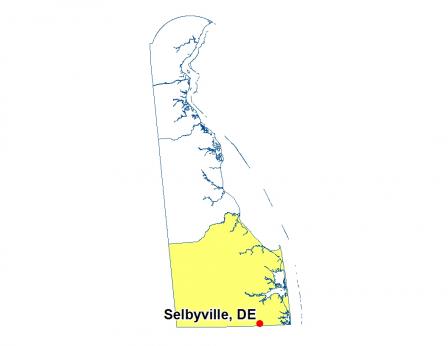

Selbyville, Delaware • May 7, 2015

The wastewater treatment plant in Selbyville, Delaware, is benefitting from an EPA-Delaware partnership designed to help water and wastewater facilities save energy and money while cutting pollution that contributes to climate change.

Treatment plants use large amounts of energy to process and move either drinking water or wastewater. These facilities are typically a municipal government’s largest energy user, accounting for up to 30 percent of a town’s total energy consumption.

The Selbyville plant has generated savings by changing a key process at its biosolids facility, installing a timer to run a large aerator intermittently rather than 24/7. The adjustment is helping to reduce power needs and still meet treatment requirements.

The operational change – the first in what may be a series of energy-saving steps at the plant – followed an energy assessment by the Delaware Water/Wastewater Energy Efficiency Partnership.

The partnership includes the Net Zero Energy team in EPA’s Mid-Atlantic Water Protection Division, the Delaware Department of Natural Resources and Environmental Control, Delaware Health and Social Services, the University of Delaware, Delaware Technical & Community College and others.

The Selbyville review was one of five conducted at treatment plants in Delaware over the past year. The assessments have helped operators and managers better understand energy usage at their plants, and identified low- or even no-cost options for achieving reductions – from adjusting treatment techniques to minimizing electricity use. These energy-saving practices have been shared with a wider audience through three workshops for key plant personnel.

Bettina Stern, operations manager at the Selbyville plant, says that while the exact cost savings of the process changes are being calculated, she’s looking for additional ways to save energy. “I’d like to do more,” she said.

The EPA energy team is next scheduled to work with treatment plants in Maryland and Virginia. The focus on energy efficiency and renewable energy at the plants is consistent with EPA’s efforts to combat climate change.

- Energy Efficiency Team Helping Delaware Towns Find Savings (PDF)(1 pg, 681 K, 2015-05-07)