Ferroalloy Manufacturing Effluent Guidelines

![]() EPA promulgated the Ferroalloy Manufacturing Effluent Guidelines and Standards (40 CFR Part 424) in 1974 and 1975. The regulation covers direct

EPA promulgated the Ferroalloy Manufacturing Effluent Guidelines and Standards (40 CFR Part 424) in 1974 and 1975. The regulation covers direct![]() direct dischargerA point source that discharges pollutants to waters of the United States, such as streams, lakes, or oceans. and indirect

direct dischargerA point source that discharges pollutants to waters of the United States, such as streams, lakes, or oceans. and indirect![]() indirect dischargerA facility that discharges pollutants to a publicly owned treatment works (municipal sewage treatment plant). dischargers. The Effluent Guidelines and Standards are incorporated into NPDES permits for direct dischargers, and permits or other control mechanisms for indirect dischargers (See Pretreatment Program).

indirect dischargerA facility that discharges pollutants to a publicly owned treatment works (municipal sewage treatment plant). dischargers. The Effluent Guidelines and Standards are incorporated into NPDES permits for direct dischargers, and permits or other control mechanisms for indirect dischargers (See Pretreatment Program).

- What is the Ferroalloy Manufacturing Industry?

- Related Categories

- Facilities Covered

- Rulemaking History

- Additional Information

What is the Ferroalloy Manufacturing Industry?

- Blast furnace

- Electric smelting furnace

- Alumina- or silicothermic process

- Electrolytic deposition.

- Silicon alloys (ferrosilicon and calcium silicide)

- Chromium alloys (high carbon ferrochromium in various grades and ferrochrome-silicon)

- Manganese alloys (standard ferromanganese and silicomanganese).

- 331111 Iron and Steel Mills

- 331112 Electrometallurgical Ferroalloy Product Manufacturing

Note: The NAICS listing is provided as a guide and does not define the coverage of the Ferroalloy Manufacturing category. For precise definitions of coverage, see the applicability sections in 40 CFR Part 424.

Wastewater is generated mainly as thermal pollution, and from air pollution control devices (baghouses, wet scrubbers and electrostatic precipitators).

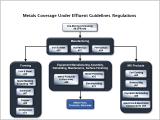

Facilities Covered

- Open Electric Furnaces with Wet Air Pollution Control Devices

- Covered Electric Furnaces and Other Smelting Operations with Wet Air Pollution Control Devices

- Slag Processing

- Covered Calcium Carbide Furnaces with Wet Air Pollution Control Devices

- Other Calcium Carbide Furnaces

- Electrolytic Manganese Products

- Electrolytic Chromium

Rulemaking History

1975 Amendment

- Documents, including:

- Interim Final Rule (February 24, 1975)

- Development Documents

Industry description, wastewater characterization, treatment technologies, regulatory compliance cost estimates and pollutant loadings for the final rule:- Calcium Carbide Segment (February 1975)

- Electrolytic Ferroalloys Segment (February 1975)

1974 Initial Rulemaking

- Documents, including:

- Final Rule (February 22, 1974)

- Development Document – Smelting and Slag Processing Segment (February 1974)

Industry description, wastewater characterization, treatment technologies, regulatory compliance cost estimates and pollutant loadings for the final rule - Proposed Rule (October 18, 1973)

Additional Information

For additional information regarding Ferroalloy Manufacturing Effluent Guidelines, please contact Ahmar Siddiqui (siddiqui.ahmar@epa.gov) or 202-566-1044.