2014 Major Criminal Cases

On This Page

Clean Air Act

Tonawanda Coke Gets One of Largest Air Pollution Fines Levied At a Federal Criminal Trial

In March 2014, Tonawanda Coke Corporation (TCC) was ordered to pay a $12.5 million penalty and make $12.2 million in community service payments for criminal violations of the Clean Air Act (CAA) and the Resource Conservation and Recovery Act (RCRA). TCC was convicted by a federal jury in March 2013 on 11 counts of violating the CAA and three counts of violating the RCRA. The fine is one of the largest fines ever levied in an air pollution case involving a federal criminal trial. The company’s environmental control manager, Mark L. Kamholz was convicted of 11 counts of violating the CAA, one count of obstruction of justice and three counts of violating the RCRA, and was sentenced to one year in prison, 100 hours of community service, and a $20,000 fine.

According to evidence presented at trial, Tonawanda Coke released coke oven gas containing benzene into the air through an unreported pressure relief valve. In addition, a coke-quenching tower was operated without baffles, a pollution control device required by TCC’s Title V Clean Air Act permit designed to reduce the particulate matter that is released into the air during coke quenches. In addition, prior to an inspection conducted by EPA in April of 2009, Kamholz told another TCC employee to conceal the fact that the unreported pressure relief valve, during normal operations, emitted coke oven gas directly into the air, in violation of the TCC’s operating permit.

Tonawanda Coke and Kamholz also stored, treated and disposed of hazardous waste without a permit to do so, in violation of RCRA. These offenses related to Tonawanda Coke Company’s practice of mixing its coal tar sludge, a listed hazardous waste that is toxic for benzene, on the ground in violation of hazardous waste regulations. For more information, read the complete case summary.

Citgo Sentenced to Pay More than $2 Million for Environmental Crimes at Corpus Christi Refinery

CITGO failed to use nets to prevent birds from landing in the open top tanks.CITGO Petroleum Corporation and CITGO Refining and Chemicals Company LLP were sentenced in February 2014 to pay a fine of $500,000 on each of the two Clean Air Act counts of conviction. CITGO Refining and Chemicals Company LLP was ordered to pay a fine of $500,000 on each of the federal Clean Air Act counts of conviction plus $15,000 on each of the three misdemeanor Migratory Bird Treaty Act conviction, for a total of $45,000.

The violations related to Citgo’s illegal operation of two massive tanks at its Corpus Christi East Plant Refinery between January 1994 and May 2003. The tanks were operated as oil water separators and required emission control equipment, which Citgo did not have. The failure to equip the tanks with emission controls exposed numerous residents in the Oak Park and Hillcrest communities to chemical emissions. Approximately 80 victims appeared in the full court room. For more information, read the complete case summary.

California Men Sentenced for Asbestos Abatement Violations at Former Air Force Base

Garbage bags with regulated asbestos containing pipe insulation.Patrick Bowman and Rudolph Buendia III were sentenced in March 2014 for violating the asbestos work-practice standards of the National Emissions Standards for Hazardous Air Pollutants. Bowman was sentenced to 27 months in prison and Buendia to 24 months in prison. Sentencing is pending for another defendant, Joseph Cuellar. A restitution hearing as to all three defendants is also pending.Joseph Cuellar was the administrative manager of Firm Build Inc., Patrick Bowman was its president, and Rudolph Buendia was its construction project site supervisor. From September 2005 to March 2006, Firm Build operated a demolition and renovation project in the former Castle Air Force Base in Atwater, California. They were to turn a building into a mechanic training center and hired local high school students from the Workplace Learning Academy in Merced to perform some of the renovation.Regulated asbestos containing material wrapped steam pipe attached to a heater suspended from the ceiling.According to court documents, the students and other employees removed and disposed of approximately 1,000 linear feet of pipe insulation and additional tank insulation which the defendants knew contained regulated asbestos-containing material without utilizing proper protective equipment (in the form of Tyvek suits, full-face respirators, bootie or footwear coverings, gloves, hair hoods or caps, and shower equipment) or taking protective measures (wetting the asbestos containing materials, sealing the asbestos debris in secure plastic bags, using negative air pressure in the building) in violation of federal law. Asbestos became air-borne during this illegal asbestos abatement. In performing the asbestos abatement project in this manner, defendants knowingly exposed Firm Build employees, Workplace Learning Academy students, as well as other subcontractors and their employees to hazardous airborne asbestos. For more information, read the complete case summary.Texas Man Gets Jail Time and Ordered to Pay Restitution in Fraud Case

In August 2014, Michael G. Johnson was sentenced to 28 months in federal prison and ordered to pay $354,529 in restitution, following his guilty plea in January 2014 to felony offenses stemming from an EPA investigation into violations of the Clean Air Act. Specifically, Johnson pleaded guilty to one count of wire fraud and one count of making false statements under the Clean Air Act. He has been in federal custody since his arrest in July 2013.

Example of a vehicle owned by victim distributors. The vehicles were "tested" by Systems Launch and issued certificates of conformity. EPA officially informed the distributors that the tests were falsified and that they cannot sell them in the U.S.From 2007 through 2009, Johnson owned and operated System Launch Associates from an apartment in Fort Worth, TX. After 2009, Johnson conducted business from Austin, Texas; Dallas, Texas; Sterling Heights, Michigan; and Miles City, Montana. Pursuant to the Clean Air Act, manufacturers are prohibited from selling a vehicle or engine that is subject to emission standards unless the vehicle or engine is covered by an EPA-issued Certificate of Conformity. System Launch purported to arrange testing of new vehicles and new vehicle engines for U.S. distributors of foreign-made vehicles. System Launch itself, however, did not perform the testing. In fact, the testing was never done, and Johnson fabricated the testing data.

Johnson instructed his clients to have the vehicles delivered to him or to a test lab he chose, instructing them to pay half of the testing/application fee to him upfront and the remainder when the testing was completed. After Johnson submitted the completed Certificate of Conformity application to the EPA, he provided a copy of the fraudulent vehicle test data to his clients. From August 2009 through June 2012, Johnson submitted multiple Certificates of Conformity applications containing fraudulent vehicle test data to the EPA and delivered that data to more than a dozen clients. The applications Johnson submitted were approved, and the EPA issued Certificates of Conformity based on fraudulent data he provided. For more information, see the complete case summary.

Clean Water Act

Ohio Company Owner Sentenced to More Than Two Years in Prison for Discharging Fracking Waste into River TributaryThe storm sewer outfall in which Lupo directed an employee to discharge waste liquid. The outfall ultimately flows into the Mahoning River.Benedict W. Lupo, the owner of Hardrock Excavating LLC, was sentenced in August 2014 to 28 months in prison and fined $25,000 for violating the Clean Water Act by dumping fracking waste into a tributary of the Mahoning River. Lupo was found guilty earlier of one count of making an unpermitted discharge. The illegal discharges took place more than 30 times between November 1, 2012 and January 31, 2013. Lupo’s company provided services to the oil and gas industry in Ohio and Pennsylvania, including the storage of brine and oil-based drilling mud used in hydrofracturing, or fracking.

On or about November 1, 2012, Lupo directed employees to empty some of the waste liquid stored at the facility into a nearby wastewater drain. There were approximately 58 mobile storage tanks at the facility and each holds approximately 20,000 gallons. Lupo directed the employees to conduct this activity only after no one else was at the facility and only after dark. On numerous occasions over the next several months, Lupo directed employees to empty some of the waste liquid into a nearby stormwater drain using a hose. The drain flowed into a tributary of the Mahoning River and ultimately into the Mahoning River. The last time an employee emptied some of the waste liquid into the drain was on or about Jan. 31, 2013. The waste liquid that night included brine and drill cuttings. A sample of the discharge taken that night was black in color and a subsequent analysis showed the presence of several hazardous pollutants, including benzene and toluene. Mark Goff and Michael Guesman previously pleaded guilty to their roles in the crime and were each sentenced to three years of probation and 300 hours of community service. For more information, see the complete case summary.

Unilever Pays $4.5 Million for Violating CWA at Connecticut Facility

Unilever Home & Personal Care USA was sentenced in April 2014 to three years of probation and fined $1 million for violating the Clean Water Act at its former manufacturing site in Clinton, Connecticut, in 2008. As part of the resolution of this case, Unilever also is contributing $3.5 million to state and local environmental programs, and instituting a new environmental compliance program at its U.S. manufacturing facilities. Unilever’s Clinton manufacturing facility produced a variety of health and beauty products for sale in the United States. The wastewater produced by the plant was regulated by a permit that prohibited the company from bypassing any portion of its wastewater treatment system unless the bypass was unanticipated, unavoidable, and necessary to prevent loss of life, personal injury or severe property damage. The permit further required that Unilever notify authorities within two hours of becoming aware of any bypass, and submit a written report within five days setting forth the cause of the problem, the duration of the event including dates and times, and corrective actions taken or planned to prevent future occurrences.

Unilever FactoryOn December 5, 2008, a third party contract employee noticed that a hose was being used to bypass the industrial process wastewater treatment system by allowing the contents of a 4,500 gallon vacuum filter filtrate tank to discharge directly to a storm drain pipe that led to Hayden Creek. Upon making this discovery, the contract employee alerted the junior wastewater treatment operator for the Clinton facility and showed him the hose and ongoing wastewater bypass. These two individuals then shut off the hose. The contract employee then notified his non-Unilever supervisor about his observations, and was urged to notify the Safety, Health and Environmental (SHE) manager of the Clinton facility. The SHE manager notified the plant manager, took pictures, and observed the downstream oil/water separator. Despite the requirement that the Connecticut Department of Energy and Environmental Protection (DEEP) be notified within two hours of the detection of such a bypass, Unilever chose not to notify the DEEP within this two-hour window.

On December 8, 2008, three days after being notified of the illegal discharge, the Unilever plant manager interviewed the two wastewater treatment operators and the contract employee who had initially discovered the bypass. All three individuals denied any responsibility for the bypass and indicated that they did not know who was responsible, although the contract employee again stated that he believed that the senior operator was responsible. Unilever conducted its own internal investigation of the December 2008 incident. In subsequent conversations and written communications with federal and state authorities throughout 2009 and 2010, Unilever claimed it was unable to conclusively determine who was responsible for the bypass, and mischaracterized the incident as an isolated, “one-off” incident that may have been the work of unknown “vandals.

An extensive EPA investigation revealed the truth about what had happened. The junior operator admitted to the EPA that he intentionally bypassed the system on December 5. EPA further concluded that for an extended period of time, perhaps as long as two years prior to December 2008, the wastewater treatment operators routinely bypassed the system on a weekly basis, discharging approximately 1,500 gallons of partially treated wastewater at a time to the storm drain that led to Hayden Creek. EPA’s investigation established that these bypasses were concealed from and unknown to Unilever management, including the SHE manager and the plant manager. Unilever’s management was aware, however, both that the operators were not properly overseeing the wastewater treatment system and that the system was not properly functioning. In December 2012, Unilever ceased manufacturing operations at the Clinton facility. For more information, see the complete case summary.

Illinois Gear Manufacturing Firm Agrees to $1.5 Million CWA Fine for Illegal Discharges into Public Sewer System

Totes containing acid wastes at Brad Foote Gear Works, Inc.Brad Foote Gear Works, Inc, a suburban Cicero, Illinois, gear manufacturing company, agreed to pay a $1.5 million fine in February 2014 for illegally discharging industrial wastewater into a public sewer system. Under terms of the agreement, Brad Foote will pay the fine in three $500,000 installments over three years. Brad Foote pleaded guilty in November 2013 and began cooperating with the government and taking remedial water treatment measures after federal environmental agents executed a search warrant in February 2011.

Brad Foote Gear Works pleaded guilty to one count of violating the federal Clean Water Act on at least 300 separate days between April 2007 and February 2011. The company, which manufactures precision gear parts for wind turbines, among other things, admitted illegally discharging spent acid wastewater and spent alkaline wastewater, industrial rinse waters, acidic solutions, oil, grease, and metal bearing wastewater into the Metropolitan Water Reclamation District of Greater Chicago sewer system without a permit. The wastewater was received at the MWRDGC’s Stickney Water Reclamation Plant in southwest Chicago, where it was treated and discharged into the Chicago Sanitary and Ship Canal.

Following the search of its premises in February 2011, the company began cooperating and implementing protocols to ensure the proper discharge and disposal of industrial wastewater from its facility. As a result, the government did not seek a court-imposed corporate compliance agreement. According to the plea agreement, Brad Foote’s manufacturing operations included a nital etch line, in which finished parts were dipped into a series of tanks containing caustic cleaners, rinse waters, and nitric acid and hydrochloric acid solutions. The etching acids and caustic cleaners of the nital etch line generally exhibited impermissibly low acidic solutions and impermissibly high alkaline solutions and, over time, those solutions and rinse waters became “spent,” meaning they lost their effectiveness and needed to be replaced.

Beginning in 2004, the company’s then chief executive officer and the manager of the nital etch line created a piping system that allowed untreated wastewater to be discharged into the public sewer system. The discharged wastewater from acid and alkaline tanks generally exhibited a pH of less than 2.0 or greater than 10.5. A second source of illegal discharge involved the company’s “Superfinish” process that used chemicals and abrasive sand-like material to smooth and polish gear parts. As a significant industrial user, Brad Foote was required to have a valid discharge authorization permit to discharge these wastewaters into the sewer system. Brad Foote knew that it did not have, and never applied for, a discharge authorization permit. For more information, see the complete case summary.

Alabama Real Estate Developer Sentenced to Jail for Filling Protection Mississippi Wetlands

Dredged material that was placed in wetlands and an aerial perspective of the disturbance.William R. “Rusty” Miller, a real estate developer from Fairhope, Alabama, was sentenced in April 2014 for the unpermitted filling of wetlands near Bay St. Louis, Mississippi, in violation of the Clean Water Act. Miller was sentenced to serve 15 months, with nine months in prison and six months in home confinement, to be followed by one year of supervised release. He was also ordered to pay a $15,000 fine and to pay $19,246 in restitution. Miller admitted to having caused the excavation and filling of wetlands on a 1,710 acre parcel of undeveloped property in Hancock County, Mississippi. Miller was identified as a part-owner of corporations that purchased and intended to develop the land.

According to the felony information, in 2001 when Miller and his companies acquired the property, he was informed by a wetland expert that as much as 80 percent of the land was federally protected wetland connected by streams and bayous to the Gulf of Mexico and as such could not be developed without a permit from the U.S. Army Corps of Engineers. In spite of this notification, Miller hired excavation contractors to trench, drain and fill large portions of the property to lower the water table and thus to destroy the wetland that would otherwise be an impediment to commercial development.; In pleading guilty, Miller has acknowledged that he knowingly ditched, drained and filled wetlands at 10 locations on the Hancock County property without having obtained a permit from the U. S. Army Corps of Engineers.

Hancock County Land LLC (HCL), the principal owner of the land, previously entered a guilty plea to related charges. The corporation was ordered to pay a total penalty of $1 million and ordered to perform community service by completing wetland restoration and preservation plans ordered by the court. These require the defendant to replant with appropriate native vegetation the wetland area it excavated and filled, donate approximately 272 acres of the southwest quadrant to the Land Trust for the Mississippi Coastal Plain to be preserved in perpetuity, to fund its management and maintenance, to pay $100,000 toward the litigation costs of the Gulf Restoration Network and to pay a civil penalty to the United States Treasury for the amount of $95,000. For more information, see complete case summary.

Washington State Man Gets Prison Term for Illegal Sewage Dumping Scheme

Video surveillance image that captured an illegal discharge occurring at All-Out Sewer and Drain Service, Inc. Encircled area shows hose from tank inserted into drain.In April 2014, Ray Caldwell and his company, All-Out Sewer and Drain Service, Inc., a septic tank pumping business, of Longview, Washington, were sentenced for multiple felony criminal violations of the Clean Water Act. Caldwell was sentenced to 27 months in prison, three years of supervised release, and a fine of $250,000 for twenty-five counts of violating the Clean Water Act, six counts of mail fraud, and two counts of making false statements. The company shares in the $250,000 fine and will be on probation for three years.

According to records filed in the case, the defendants’ scheme to defraud the City of Longview, Cowlitz County, and the Three Rivers Regional Wastewater Authority went on for more than ten years. All-Out was engaged in the business of pumping, hauling, and disposing of septic tank waste, grease trap waste, and industrial wastewater. It was All-Out’s practice to transport the waste to its facility in Longview where it was minimally treated and stored in a 10,000 gallon storage tank. While some of the tank contents were appropriately trucked to approved treatment facilities, a majority of the commingled waste was routinely dumped down an unauthorized sewer port located on the All-Out facility.

Based on video surveillance footage seized by law enforcement authorities, Caldwell and his business partner, Randy Dingus, undertook the illegal discharges in the early morning hours, under the cover of darkness, to avoid being detected by passersby or unsuspecting employees. When a records review conducted by the City of Longview in 2010 threatened to expose the scheme, the defendants began submitting false documents underreporting the true volume of trucked and hauled waste. This deception worked until August 2012 when law enforcement surveillance activities prompted by citizen complaints revealed the early morning dumping. For more information, see the complete case summary.

Former Illinois Village Water Officials Sentenced for Concealing Village’s Use of Well in Drinking Water Supply

Frank Scaccia, a retired certified water operator, and Theresa Neubauer, former water department clerk and supervisor and, later, police chief of the southwest suburban village of Crestwood, Illinois, were each sentenced in November 2013, to two years’ probation for lying repeatedly to environmental regulators for more than 20 years about using a water well to supplement the village’s drinking water supply. The defendants, effectively thwarted the government from implementing the federal Safe Drinking Water Act’s notice and testing requirements designed to ensure the safety of municipal water supplies. In addition to probation, Scaccia was ordered to serve the first six months in home confinement. He pleaded guilty on April 11, 2013, to making false statements. Neubauer was fined $2,000 and ordered to perform 200 hours of community service. She was convicted by a jury on April 29, 2013, of 11 counts of making false statements after a week-long trial.

The pump that the Village of Crestwood used to draw water from an underground aquifer, which was used to supplement their drinking water drawn from Lake Michigan. This picture was taken after the pump was already disconnected from the well and taken out of service.Both defendants concealed the village’s use of its well from the government and the citizens of Crestwood to save money. By doing so, the village didn’t properly monitor for contaminants that could have been introduced to Crestwood’s water supply, avoided having to fix its leaking water distribution system, or paying the neighboring village of Alsip more money for water drawn from Lake Michigan. Due to Crestwood’s use of Well #1, an unmonitored and unreported water source, the village should have periodically tested its drinking water for organic contaminants, inorganic contaminants, and radiological contaminants beginning in the 1970s. Between 1987 and 2008, Scaccia and Neubauer were among a small circle of trusted village, who concealed that Crestwood was supplementing its Lake Michigan water with water drawn from Well #1

According to court records and the evidence at trial, since at least 1973, the substantial majority of Crestwood’s drinking water came from Lake Michigan and was purchased from neighboring Alsip, which, in turn, had purchased the water from the city of Chicago after it was treated and tested pursuant to state and federal environmental regulations. Since 1982, Crestwood regularly supplemented the Lake Michigan water with water drawn from an underground aquifer through a well located on Playfield Drive, known as Well #1. Crestwood found it necessary to supplement the Lake Michigan water with water pumped from Well #1, in part, because of substantial leakage in its water distribution system, which Crestwood officials failed to adequately repair. For more information, see the complete case summary.

Kentucky Oil Well Operators Sentenced for Violations of the Safe Drinking Water Act

Charles L. Stinson and Ralph Dowell operators of Logsdon Valley Oil Co. Inc., were sentenced to two years’ probation in January 2014 for violations of the Safe Drinking Water Act. Stinson and Logsdon Valley Oil Co. Inc., were ordered to pay fines for the continued conspiracy to inject fluids, without a permit, into sinkholes and wells in Hart County, Kentucky, from March 13, 2008 through July 18, 2012.

According to the plea agreement, Stinson and Logsdon Valley Oil Co. Inc., agreed to a fine of $45,000 to be paid at sentencing. According to the terms, Stinson was to pay the fine personally, with $25,000 paid to the Commonwealth of Kentucky, $10,000 to the EPA and $10,000 to the United States. Also, as part of the terms, Stinson agreed to provide adequate documentation to EPA that the Stinson #6 (the well-used for illegal injection) is plugged and abandoned in such a manner that protects underground sources of drinking water from contamination. Stinson and Dowell pleaded guilty to violating a requirement of an applicable underground injection control program. Specifically, they configured piping to inject produced brine water (fluids brought to the surface in connection with oil production) from the tank battery to sinkholes, and injected produced brine water into a sinkhole, and conveyed fluids into sinkholes. For more information, see the complete case summary.

Oklahoma-based oil and gas Production Company ordered to pay $1M for 2011 oil spill

In January 2014, Nadel and Gussman Rockies, LLC, (NGR), an oil and gas production company based in Tulsa, Oklahoma, was ordered to pay a total of $1 million in fines, restitution and community service contributions after previously leading guilty to Clean Water Act violations stemming from its role in the illegal discharge of more than 4,700 gallons of crude oil into a tributary of the North Platte River near Rawlins, Wyoming. The company was also required to implement a new compliance program to ensure future compliance with all environmental laws and regulations applicable to oil and gas companies leasing lands from the federal government.

NGR was ordered to pay a $357,500 criminal fine and a total of $430,500 in restitution, of which $200,000 will go to the Oil Spill Liability Trust Fund, a federal fund used to finance oil spill response activities and provide compensation for damages. The remaining $230,500 will go to Carbon County, Wyoming, the county in which the oil spill occurred. Of that amount, $80,500 will be used to purchase equipment and supplies necessary to responding to and cleaning up oil spills in the county, while the remaining $150,000 will be equally distributed to the Little Snake River, Saratoga-Encampment-Rawlings, and Medicine Bow Conservation Districts to improve water quality and conserve local natural resources. NGR will also make a community service payment of $212,000 to be divided equally between the Yellowstone Park Foundation and the Grand Teton National Park Foundation for projects to enhance, protect and preserve the natural resources of each park.

The case began in May 2011 when a local resident noticed an oily sheen on Emigrant Creek near Rawlins. BLM employees confirmed there had been a discharge of oil into the creek and that it appeared to have originated from an oil tank storage system owned and operated by NGR. BLM requested EPA’s assistance for emergency clean-up. A joint criminal investigation conducted by EPA’s Criminal Investigation Division and BLM’s Special Investigation Group later determined that Patrick Ely, an independent contractor for NGR, routinely drained production water from NGR’s tank system directly to the ground as authorized by NGR Operations Manager, Hugo Cartaya. As a result, about 375,000 gallons of production water containing high levels of arsenic and 113 barrels of oil – approximately 4,746 gallons – were discharged in mid-April, 2011. Although Ely reported the oil spill to NGR Operations Manager Hugo Cartaya, the spill went unreported to the National Response Center until directed by the BLM and EPA. NGR pleaded guilty in November 2013 to violating the CWA by negligently discharging a harmful quantity of oil into a waterway under federal jurisdiction. In April 2014, Cartaya was sentenced to serve three years of supervised probation, was ordered to serve 250 hours of community service, and was ordered to pay a $10,000.00 fine after pleading guilty to making false statements. For more information, see the complete case summary.

Resource Conservation and Recovery Act (RCRA)

Georgia Hazardous Waste Transporter Sentenced

Assessment and removal of hazardous waste Lewis illegally stored inside storage unit at Bass at Wesleyan self storage..Robert Lewis, was sentenced in March 2014 to serve 10 months in federal prison for the unlawful storage of hazardous waste. Lewis entered a guilty plea to the charges in September 2013. In his plea agreement, Lewis admitted that he owned and operated a waste hauling business under the name of Simple Solutions, Inc. From about May 2007 until April 2008, Lewis transported hazardous waste, generated by a local manufacturing plant, to a licensed disposal facility.

On February 26, 2009, forty 55-gallon drums and sixteen 275-gallon totes of this hazardous waste material were found to be improperly stored at a self-storage facility in Macon, Georgia. The units had been rented by Lewis in July 2007. Lewis rented four additional units in August 2007. It was also determined that Lewis had improperly stored hazardous waste, including highly flammable solvents and highly toxic cyanide wastes, in Rex, Georgia, and at his home in Albany, Georgia. For more information, see the complete case summary.

Owner of Colorado Aircraft Painting Company Sentenced for Unlawfully Treating Hazardous Waste

Norman Teltow, owner of Gold Metal Paint Co. LLC (GMP), was sentenced in November 2013 to serve six months home confinement with electronic monitoring, pay a $10,000 criminal fine, and serve two years of probation. Teltow pleaded guilty in March 2013 to illegally treating hazardous waste at the company’s facility. Teltow operated GMP out of a hangar near the Front Range Airport in Watkins, Colorado. GMP was primarily in the business of painting small aircraft. During the course of its business, GMP created hazardous waste in the form of spent methylene chloride-based solvents mixed with paint waste. GMP was required to use a licensed waste management company to transport the hazardous waste to a licensed facility for disposal. However to avoid the costs associated with proper disposal, Teltow directed GMP employees to store the spent solvents in an under ground tank below the facility knowing that it was illegal to store the waste in that manner.

Gold Metal Paint Co. stripper hangar showing methylene chloride stripper waste drain.

When the Colorado Department of Public Health and Environment (CDPHE) became aware of the situation, it conducted an inspection and ordered Teltow to hire a licensed waste management company to pump the waste out of the tank and dispose of it properly. CDPHE further ordered that the tank be cleaned, that the trench drain leading to the underground tank be sealed, and that GMP use a licensed waste management company to transport all hazardous waste in the future. In response to CDPHE’s orders, Teltow hired a licensed waste management company to pump out the tank, and sealed off the trench drain to the underground tank. However, rather than hire a licensed waste management company to clean out the tank, Teltow ordered subordinate employees to clean out the tank without the benefit of any personal protective equipment, exposing them to hazardous waste containing methylene chloride. The employees suffered from headaches, dizziness, and nausea as a result. Teltow then devised a new plan for treating the hazardous waste by “evaporating” it into the atmosphere. Teltow ordered his employees to pour the hazardous waste onto the floor of the hangar at the end of the work day and then leave the hangar doors ajar to allow the waste to evaporate. When Teltow’s “evaporation” method was unsuccessful at treating all of the waste that GMP accumulated, Teltow drilled open the trench drain ordered sealed by CDPHE so that the waste could again flow into the underground tank. For more information, see the complete case summary.

Former President of Port Arthur, Texas, Chemical Company Sentenced for Federal Crimes Related to Employee Deaths

Matthew Lawrence Bowman, the former president of a Port Arthur, Texas, Chemical Company, was sentenced in October 2013 for occupational safety crimes which resulted in the death of an employee. He pleaded guilty in May 2013 to violating the Occupational Safety and Health Act and making a false statement and was sentenced to serve 12 months in federal prison and ordered to pay fines in the amount of $5,000. Bowman admitted to not properly protecting PACES employees from exposure to hydrogen sulfide, a poisonous gas resulting in the death of truck driver Joey Sutter on Dec. 18, 2008. In addition, Bowman admitted to directing employees to falsify transportation documents to conceal that the wastewater was coming from PACES after a disposal facility put a moratorium on all shipments from PACES after it received loads containing hydrogen sulfide.

Port Arthur Chemical and Environmental Services facility.Bowman was president and owner of PACES, located in Port Arthur and CES Environmental Services located in Houston. PACES was in operation from November 2008 to November 2010, and was in the business of producing and selling caustic materials to paper mills. The production of caustic materials involved hydrogen sulfide, a poisonous gas. According to the National Institute for Occupational Safety and Health, hydrogen sulfide is an acute toxic substance that is the leading cause of sudden death in the workplace. Employers are required by OSHA to implement engineering and safety controls to prevent employees from exposure above harmful limits of hydrogen sulfide.

Bowman was responsible for approving and directing PACES production operations, the disposal of hydrogen sulfide wastewater, and ensuring implementation of employee safety precautions. In some cases, Bowman personally handled the investigation of work-related employee injuries, directed the transportation of PACES wastewater, and determined what safety equipment could be purchased or maintained. In the cases at issue, hazardous materials were transported illegally with false documents and without the required placards. Most importantly, the workers were not properly protected from exposure to hazardous gases. The exposure resulted in the deaths of two employees, Joey Sutter and Charles Sittig, who were truck drivers, at the PACES facility on December 18, 2008 and April 14, 2009. Placarding is critical to ensure the safety of first responders in the event of an accident or other highway incident. Bowman and PACES were indicted by a federal grand jury on July 18, 2012. For more information, see the complete case summary.

Former Texas Logistics Company Manager Sentenced for Falsifying Shipping Documents

Ryan Thomas, former logistics manager for CES Environmental Services in Houston, Texas, was sentenced in July 2014 to 12 months’ probation, ordered to pay a $500 fine, and serve 100 hours of community service for falsifying shipping documents related to the transportation of hazardous materials.

Thomas produced manifests that indicated that three tanker truckloads of wastewater originated from CES' Houston plant when in fact, they were produced and shipped from CES' Port Arthur (PACES) plant. The PACES location was placed on a moratorium after a November 3, 2008, accident in which a CES driver was overcome by vapors released during the offloading of wastewater. The disposal facility placed the moratorium on all loads of waste-water from the PACES location until the cause of the accident could be identified and new inbound load testing protocols were agreed to. For more information, see the complete case summary.

Title 18 Cases

North Carolina Recycling Business and Owner Sentenced for Unlawful Handling of PCB-Contaminated Oil, Tax Violations, and False Statements

PCB warning sign posted at entry on P&W Waste Services building.Benjamin Franklin Pass, owner and operator of P&W Waste Oil Services, Inc., was sentenced in July 2014 to 42 months in prison and ordered to pay restitution of more than $21 million for clean-up costs associated with the environmental contamination at his business and an additional $539,000 to the Internal Revenue Service for federal income taxes he failed to pay between 2002 and 2011.

P&W Waste Oil Services, Inc. was ordered to pay restitution of more than $21 million for losses incurred by Colonial Oil and International Paper as a result of the mishandling of used oil contaminated with polychlorinated biphenyls (PCB) that led to widespread contamination and millions of dollars in clean-up costs. P&W was also ordered to serve a five-year term of probation and to take remedial action to address the environmental contamination at its facility and other leased property in eastern North Carolina.

P&W collected, processed and marketed used oil from automotive service stations, transformer repair companies and marinas. P&W was not authorized to handle or store used oil containing more than two parts per million (ppm) of PCBs, man-made organic chemicals that are known carcinogens. Law enforcement learned that in 2009 and again in 2010, Pass and P&W falsely certified that its employees had taken requisite training on the handling of hazardous wastes and that, between 2002 through 2011, Pass failed to pay his federal income taxes despite having the ability to pay. For more information, see the complete case summary.

Alabama Pest Control Company and Its Owner Plead Guilty to Unlawful Application of Pesticides at Georgia Nursing Homes

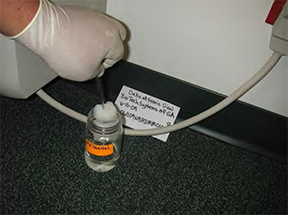

Georgia Department of Agriculture inspector taking samples to be tested for the presence of Termidor inside the nursing home.Steven A. Murray and his company, Bio-Tech Management, Inc., pleaded guilty in March 2014 to charges of conspiracy, unlawful use of pesticides, false statements and mail fraud in connection with the misapplication of pesticides in Georgia nursing homes.

According to the plea agreement, from October 2005 to June 2009, Murray and Bio-Tech provided monthly pest control services to nursing homes in Georgia by spraying pesticides in and around their clients’ facilities. Bio-Tech employees routinely applied the pesticide Termidor indoors, contrary to the manufacturer’s label instructions. After the Georgia Department of Agriculture made inquiries regarding Bio-Tech’s misuse of Termidor and other pesticides, Murray directed several of his Bio-Tech employees to alter company service reports with the intent to obstruct an investigation. For more information, see the complete case summary.