National Compliance Initiative: Reducing Accidental Releases at Industrial and Chemical Facilities

Problem

Thousands of facilities nationwide, many of which are in environmental justice communities, make, use, and store extremely hazardous substances. Catastrophic accidents at these facilities—historically about 150 each year—can result in fatalities and serious injuries, evacuations, and other harm to human health and the environment. These facilities are regulated under Clean Air Act (CAA) Section 112(r) through the chemical accident prevention regulations, also known as the Risk Management Program (RMP). The regulations apply to stationary sources that have a listed chemical in a process at or above an established threshold quantity. A broader statutory obligation under CAA § 112(r)(1), the General Duty Clause (GDC), applies to all stationary sources with regulated substances or other extremely hazardous substances, regardless of the quantity of chemical involved. The GDC requires facilities to identify hazards that may result from accidental releases by using appropriate hazard assessment techniques, designing and maintaining a safe facility, taking such steps as are necessary to prevent releases, and minimizing the consequences of those accidental releases that do occur. Facilities regulated under CAA § 112(r) are found in every state. EPA inspections have revealed significant noncompliance and an ongoing need for additional compliance assistance.

Goal

The goal of this NCI is to reduce the risk to human health and the environment by decreasing the likelihood of chemical accidents. A successful initiative would reduce communities’ risk by having regulated facilities and industry associations work to:

- improve safety;

- increase compliance with risk management plan and GDC requirements; and

- promote coordination and communication with state and local responders and communities.

Results

In FY 2020, the agency continued efforts that were initiated in the prior cycle. The following are illustrative of the agency’s efforts to reduce risks of accidental release at industrial and chemical facilities.

-

Delivered inspector training to EPA, states, local authorities, and OSHA staff

These new inspectors will enhance EPA’s ability to monitor compliance and pursue necessary enforcement actions to address violations.

-

Delivered the three-day Process Hazard Analysis (PHA) training

This specialized course for inspectors from EPA, OSHA, state, and local partners explains the PHA requirements under the Risk Management Program regulations, familiarizes participants with general hazard analysis theory, explains what is necessary to perform a complete PHA, and identify common deficiencies and issues associated with PHA execution. The hazard analysis requirements of both the Risk Management Program regulations and the General Duty Clause are fundamental to identifying the potential causes of chemical accidents and to designing processes so that they are safer and less likely to experience a chemical release.

-

Delivered Ammonia Refrigeration Systems, Technology, and Safety Training

This three-day course is designed for staff from EPA, OSHA, and state and local partners, and is specific to the operation of ammonia refrigeration systems. Ammonia refrigeration is a commonly used process throughout the United States and makes up approximately 40 percent of the facilities regulated under the Risk Management Program.

-

Finalized guidance for inspecting piping at petroleum refineries

A large number of chemical releases at petroleum refineries occur from piping systems. This guidance allows inspectors to focus their activities on ensuring that refineries are monitoring and maintaining their piping sufficiently to reduce the likelihood of accidental releases.

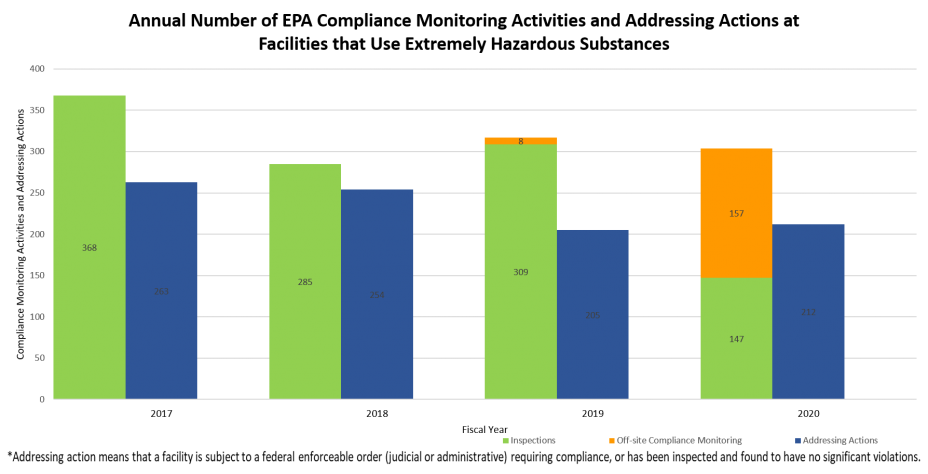

Annual Number of EPA Compliance Monitoring Activities and Addressing Actions

Map of inspections and addressing actions at facilities that use extremely hazardous substances.

Cases

EPA has addressed serious violations through enforcement actions. Examples of recently concluded enforcement actions include the following: