Electric Power Systems Partnership

Established in 1999, the SF6 Emission Reduction Partnership for Electric Power Systems is a collaborative effort between EPA and the electric power industry to identify, recommend, and implement cost-effective solutions to reduce sulfur hexafluoride (SF6) emissions. SF6 is a highly potent greenhouse gas that is used in the industry for insulation and current interruption in electric transmission and distribution equipment.

Emission Sources

The most common use for SF6, both domestically and internationally, is as an electrical insulator in high voltage equipment that transmits and distributes electricity. Since the 1950’s, the U.S. electric power industry has used SF6 in circuit breakers, gas-insulated substations and other switchgear used in the transmission system to manage the high voltages carried between generating stations and customer load centers.

Several factors affect SF6 emissions from electric power systems, such as the type and age of the SF6-containing equipment (e.g., old circuit breakers can contain up to 2,000 pounds of SF6, while modern breakers usually contain less than 100 pounds) and the handling and maintenance procedures practiced by electric utilities. Because of its long life span and high global warming potential (GWP), even a relatively small amount of SF6 can impact the climate.

The electric power industry uses roughly 80 percent of all SF6 produced worldwide. Ideally, none of this gas would be emitted into the atmosphere. In reality, significant leaks occur from aging equipment, and gas losses occur during equipment maintenance and servicing. With a GWP 22,800 times greater than carbon dioxide (CO2) and an atmospheric life of 3,200, one pound of SF6 has the same global warming impact of 11 tons of CO2.

Mitigation Options

The electric power industry can reduce the nation’s SF6 emissions through cost-effective operational improvements and equipment upgrades. Through improvements in the leak rate of new equipment, refurbishing older equipment, and the use of more efficient operation and maintenance techniques, utilities often find economical solutions to reduce SF6 emissions.

Under the partnership, EPA shares information on best management practices and technical issues to help reduce emissions. Some cost-effective options to reduce SF6 emissions are:

- Leak Detection and Repair

- Use of Recycling Equipment

- Employee Education/Training

For more information about SF6 mitigation options in the electric power systems, see EPA’s report Overview of SF6 Emissions Sources and Reduction Options in Electric Power Systems. These options are also described in a summary poster Reducing SF6 Emissions in Electric Power Systems: Best Industry Practices.

Relevant Links

- Greenhouse Gas Reporting Program Subpart DD: Use of Electric Transmission and Distribution Equipment Proposed and Promulgated Rules

- Code of Federal Regulations: Mandatory Greenhouse Gas Reporting (40 CFR Part 98)

- Electric Power Research InstituteExit

- National Electrical Manufacturers AssociationExit

Frequent Questions

- How do SF6 emissions contribute to global climate change?

SF6 is the most potent greenhouse gas known to-date. Over a 100-year period, SF6 is 22,800 times more effective at trapping infrared radiation than an equivalent amount of carbon dioxide (CO2). SF6 is also a very stable chemical, with an atmospheric lifetime of 3,200 years. As the gas is emitted, it accumulates in the atmosphere in an essentially un-degraded state for many centuries. Thus, a relatively small amount of SF6 can have a significant impact on global climate change.

- How is SF6 used in the U.S. electric power industry?

SF6 is a non-hazardous, inert gas that is used both as an arc quenching and insulating medium in high-voltage switchgear, circuit breakers and gas insulated substations. SF6-insulated equipment is predominantly used in the transmission system that manages the high voltages carried between generating stations and customer load centers. The largest use of SF6 occurs in high-voltage circuit breakers, where, in addition to providing insulation, SF6 is used to quench the arc formed when an energized circuit breaker is opened.

Disconnectors and ground switches use SF6 primarily for insulation, and individually, they contain only slightly less SF6 than a circuit breaker. These devices are used to isolate portions of the transmission system where current flow has been interrupted (using a circuit breaker). Gas-insulated substations also use a significant amount of SF6, and GIS installations house SF6-insulated circuit breakers, busbars and monitoring equipment.

Several factors affect SF6 emissions from electrical equipment, such as the type and age of SF6-containing equipment (e.g., old circuit breakers can contain up to 2,000 pounds of SF6, while more modern breakers contain less than 100 pounds) and the handling and maintenance protocols utilized by electric utilities.

- How can reducing SF6 emissions help my company?

- Save Money - Purchasing SF6 can be expensive, so reducing emissions can save money.

- Increase Grid Reliability - Use of improved SF6 equipment and management practices helps protect system reliability and efficiency.

- Protect the Environment - SF6 is the most potent greenhouse gas known. It is 22,800 times more effective at trapping infrared radiation than an equivalent amount of CO2 and stays in the atmosphere for 3,200 years.

- What can the electric power industry do to reduce SF6 emissions?

Companies are encouraged to develop an SF6 emissions reduction strategy, which involves creating an inventory of SF6-using equipment and estimating current emissions. After preparing the emissions reduction strategy, the company can then develop and implement a company-wide policy for managing the leak-rates of current equipment and to ensure the proper handling of SF6.

Join the Program

Joining the SF6 Emissions Reduction Partnership for Electric Power Systems can save money and provide your organization with recognition from the EPA as a leader in the effort to reduce greenhouse gas emissions. By becoming a partner, you join a group of electric utilities committed to voluntary and cost-effective pollution prevention.

Please use the Contact Us form to inquire about joining the Partnership or to subscribe to the Partnership Listserv.

Disclaimer

This page provides links to non-EPA websites.

Partner links exit the site. Exit

Current Partners

The table below provides the list of current partners in the SF6 Emissions Reduction Partnership for Electric Power Systems. These electric utilities companies are committed to the voluntary reduction of SF6 emissions through cost-effective operational improvements and equipment upgrades.

Since 1999, members of the U.S. electric power industry and the EPA have been working together to identify and implement opportunities to reduce SF6 emissions. As part of their commitment to the Partnership, Partners annually report their SF6 emissions and nameplate capacity estimates to EPA (Note: Under EPA’s Greenhouse Gas Reporting Program, Partners with a total nameplate capacity exceeding 17,820 pounds must report emissions and nameplate capacity under subpart DD - Use of Electric Transmission and Distribution Equipment.) EPA collects and aggregates Partner information to determine the overall accomplishments of the Partnership.

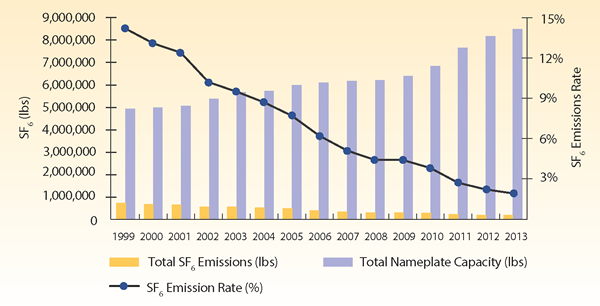

The Partnership’s average annual SF6 emission rate, the ratio of SF6 emissions relative to total SF6 nameplate capacity (i.e., the total quantity of SF6 contained in electrical equipment), is a benchmark metric by which achievements of the Partnership are tracked. As illustrated in Figure 1, the average annual SF6 emission rate of Partners has decreased drastically since 1999. In the past five years, the emission rate has halved, from over 4 percent to just below 2 percent. Overall, the average annual SF6 emission rate for the Partnership has decreased approximately 87 percent from the 1999 baseline emission rate of 14.2 percent to 1.9 percent in 2013. To date, Partners have decreased absolute emissions of SF6 by 75 percent.

The annual average SF6 emission rate of Partners has decreased drastically since 1999. In the past five years, the emission rate has halved, from over 4 percent to just below 2 percent. Overall, the annual average SF6 emission rate for the Partnership is down approximately 87 percent from the 1999 baseline emission rate of 14.2 percent to 1.9 percent in 2013.

The annual average SF6 emission rate of Partners has decreased drastically since 1999. In the past five years, the emission rate has halved, from over 4 percent to just below 2 percent. Overall, the annual average SF6 emission rate for the Partnership is down approximately 87 percent from the 1999 baseline emission rate of 14.2 percent to 1.9 percent in 2013.

View the 2014 Partnership Report for more information on the accomplishments of the Electric Power Systems Partnership.

The documents and resources below were developed under the partnership to encourage the implementation of cost-effective solutions to reduce SF6 emissions.

Service Provider Directory

- View the directory to learn about service and technology providers that can facilitate SF6 emission reduction activities.

Best Practices

- View the Moving Toward SF6-Free High Voltage Circuit Breakers: Considerations for Adopting Vacuum Breaker and Fluorinated Gas Alternative Technologies document to learn about two new high voltage circuit breaker technologies that can be used as alternatives to traditional SF6 breakers and to review considerations for technology adoption.

- View the Overview of SF6 Emissions Sources and Reduction Options in Electric Power Systems report to learn about best practices and cost-effective methods of reducing SF6 emissions that can be implemented by the electric power industry.

- A summary of best practices compiled in the report (above) is available in the poster Reducing SF6 Emissions in Electric Power Systems: Best Industry Practices.

Annual Partnership Reports

Case Studies

- Southern Cal Edison: An Asset Management Approach for EPA/CARB SF6 Regulations

- ITCTransmission Case Study

- Duquesne Light: Project Profile

- PG&E Case Study

Webinars

- SF6 Free Alternative Medium and High Voltage Circuit Breakers - Vacuum Technology - September 14, 2020

- SF6 Gas Storage Inventories - Strategies for Tracking - May 9, 2019

- SF6 Leak Monitoring - July 26, 2007

- SF6 Gas Inventory - May 31, 2007

Research & Studies

- Overview of SF6 Emissions Sources and Reduction Options in Electric Power Systems

- SF6 Nameplate Inaccuracies and their Impact on Greenhouse Gas Reporting

- 2004 – 2006 SF6 Data Summary

- SF6 Leak Rates from High Voltage Circuit Breakers - U.S. EPA Investigates Potential Greenhouse Gas Emissions Source

- Byproducts of Sulfur Hexafluoride Use in the Electric Power Industry

- Catalog of Guidelines and Standards for the Handling and Management of Sulfur Hexafluoride

- Possible Present and Future Alternatives to Pure SF6

- SF6 Sales and Distribution by End-Use Application (1961-2001)

Upcoming Events

There are no upcoming events scheduled at this time.

Previous Events

- Webinar: SF6 Free Alternative Medium and High Voltage Circuit Breakers - Vacuum Technology

September 14, 2020 - Webinar: SF6 Gas Storage Inventories - Strategies for Tracking

May 8, 2019 - 2017 Workshop on SF6 Emission Reduction Strategies

January 24-25, 2017, Embassy Suites by Hilton, San Franciso, CA - 2014 Workshop on SF6 Emission Reduction Strategies

May 6-7, 2014, Hilton Long Beach, Long Beach, CA - 2012 Workshop for SF6 Emission Reduction Strategies

April 17-18, 2012, hosted by Southern Company and Georgia Power, Atlanta, GA - 2010 Partner Meeting

May 13-14, 2010, Hosted by Oncor, Dallas, TX - 2009 Partner Meeting

June 2-3, 2009, Hosted by ComEd, Chicago, IL - 2009 Workshop for SF6 Emission Reduction Strategies

February 4-5, 2009, Hyatt Regency Phoenix in Phoenix, Arizona - Finepoint Circuit Breaker Test & Training Conference

October 1-5, 2007, Omni William Penn Hotel in Pittsburgh, Pennsylvania - 4th International Conference on SF6 and the Environment

November 2006, San Antonio, TX - 3rd International Conference on SF6 and the Environment

December 2004, Scottsdale, Arizona - 2nd International Conference on SF6 and the Environment

November 2002, San Diego, CA - 1st International Conference on SF6 and the Environment

November 2000, San Diego, CA

2014 Awards for Global Climate Protection Efforts

- Organizational and Team Leadership - Commonwealth Edison Company (ComEd) of Chicago, IL

Sally Rand, EPA, with Marvin Landeros, Lorinda Alms, and Mark Slezak from ComEdCommonwealth Edison Company (ComEd) is a unit of Chicago-based Exelon Corporation, which is an electric and gas utility holding company. ComEd is the largest electric power delivery service company in Illinois providing service to more than 3.7 million customers across Northern Illinois. ComEd does not own or operate electric power generation facilities.

Sally Rand, EPA, with Marvin Landeros, Lorinda Alms, and Mark Slezak from ComEdCommonwealth Edison Company (ComEd) is a unit of Chicago-based Exelon Corporation, which is an electric and gas utility holding company. ComEd is the largest electric power delivery service company in Illinois providing service to more than 3.7 million customers across Northern Illinois. ComEd does not own or operate electric power generation facilities.ComEd's SF6 emission reduction efforts are led by a team of representatives from the Transmission and Substation Operations (T&S) and Environmental Services departments. The SF6 team is responsible for setting annual program targets and reduction goals for SF6 as part of ComEd's overall corporate environmental goals. The team meets at the beginning of each year to review progress and identify continuous improvement opportunities and then meets throughout the year to track actions and accomplishments.

As a result of their enhanced SF6 reduction strategic planning, ComEd has decreased its SF6 leak rate in each of the past ten years. While industry average leak rates (emissions/total nameplate capacity) are 3.8%, ComEd's 2012 leak rate was 0.55% for 2012 and 0.25% for 2013. Joining in 1999, ComEd was one of the founding utilities in the EPA SF6 Emission Reduction Partnership.

- Excellence in SF6 Inventory and Data Collection Systems- New York Power Authority (NYPA), White Plains, NY

John Kahabka from New York Power Authority with Sally Rand, EPAThe New York Power Authority (NYPA) is one of New York State's leading suppliers of electricity, operating 16 generating facilities and more than 1,400 circuit-miles of transmission lines. NYPA is a state-owned and -operated public power organization and sells electric power to government agencies, community-owned electric systems and rural electric cooperatives, companies, and private utilities for resale to their customers and neighboring states.

John Kahabka from New York Power Authority with Sally Rand, EPAThe New York Power Authority (NYPA) is one of New York State's leading suppliers of electricity, operating 16 generating facilities and more than 1,400 circuit-miles of transmission lines. NYPA is a state-owned and -operated public power organization and sells electric power to government agencies, community-owned electric systems and rural electric cooperatives, companies, and private utilities for resale to their customers and neighboring states.In recognition of the importance of high quality data for use in required reporting and in the trending of equipment, the NYPA embarked on an effort to design a system to track SF6 information in an easy-to-use format while providing data reports required for external and internal greenhouse gas reporting programs.

Historically, NYPA used a simple standalone database to track pertinent SF6 data for reporting. While this program served its initial purpose well, there was room for improvement. NYPA tracks tens of thousands of pieces of varying equipment utilizing a central asset management database. This database contained valuable information on all the SF6 assets that the standalone system did not. The SF6 team realized that if they combined the two systems, it would be of great benefit.

Working over the course of 2-years, a cross-discipline team of Scientists, Engineers, and IT Database Administrators and Programmers designed and built a new platform that seamlessly joined the two systems. The new program allows the field users to log data in a simple, easy-to-use and intuitive way with on-the-fly data validation that ensures accurate data entry. Not only does this system allow quick, easy and accurate data entry, it also enables the Environmental and Planning Departments to track leak rates, nameplate capacities, bottle inventories and usage, equipment trending, and any other variable it would need to make informed decisions.

2012 Awards for Global Climate Protection Efforts

- Organizational Leadership: Commonwealth Edison Company (ComEd) of Chicago, IL

Through the efforts of ComEd’s Transmission & Substation and Environmental Service groups, ComEd has implemented a successful SF6 management program, which included:

- Enhancing the reporting and notification process associated with emissions by raising awareness and visibility of SF6 releases and the associated environmental impact.

- Purchasing leak detection cameras and implementing a winter-readiness program that proactively scans equipment for leaks during seasonal fluctuations.

- Purchasing additional gas reclaiming carts and implementing a program to properly capture gas during maintenance and repairs, which enables crews to minimize gas and productivity losses by having the equipment available within each region.

- Phasing out “First Generation” older equipment that were prone to SF6 leaks.

ComEd has also rewarded the efforts made by employees to reduce SF6 emissions by embedding the achievement of SF6 emission reduction goals into ComEd’s compensation program. These actions resulted in a significant reduction in SF6 emissions reported by ComEd in recent years relative to its 1999 baseline.

- Organizational Leadership: MidAmerican Energy Company of Des Moines, IA

In 2002, MidAmerican Energy initiated an effort to identify and replace the circuit breakers most responsible for emitting SF6 into the atmosphere. Twenty-five breakers were initially identified, and all 25 were replaced between 2002 and 2011, with the highest-emitting breakers replaced first.

MidAmerican Energy has also adopted new gas handling procedures, which include monthly reviews of usage logs and more detailed emission reports to management. In 2010, MidAmerican Energy implemented a plan to better control the handling of emissions by ensuring that all SF6 would be purchased, inventoried and installed by MidAmerican Energy’s trained personnel.

These actions resulted in a significant reduction in SF6 emissions reported by MidAmerican Energy relative to its 2004 baseline.

- Team Leadership: ITC Holdings Corp. of Novi, Michigan

ITC Holdings Corp's SF6 management team implemented a comprehensive SF6 management and equipment replacement program. This program included:

- The development of procedures and work practices through its Environmental Management System to ensure the consistent control, measurement and reporting of SF6 emissions company-wide.

- The recent purchase of two leak detection cameras to facilitate the detection of SF6 leaks.

- The purchase of 12 gas carts to increase maintenance efficiency and reduce emissions during equipment maintenance and replacement activities.

- The replacement of SF6 circuit breakers and other gas insulated switchgear that had recurring SF6 leaks.

These actions resulted in a significant reduction in SF6 emissions reported by ITC in recent years relative to its 2005 baseline.

- Technical Innovation: Consolidated Edison Company of New York (ConEd) in New York, NY

Consolidated Edison Company of New York received an award for its innovative use of ultrasonic probes to detect SF6 leaks. Using the UE Systems Ultraprobe 10,000, with the addition of a unique liquid leak amplifier spray, the company has been able to detect very small SF6 leaks that it has been unable to identify through conventional means such as sniffers, bubble sprays and gas cameras.

While this technology was originally developed for the detection of leaks in a vacuum chamber, with some minor modification and training, ConEd’s employees have successfully used it for SF6 leak detection. The process begins when a piece of equipment is suspected of having a microscopic leak. The liquid leak amplifier is sprayed onto the equipment where the leak is thought to be located. The unique formulation of the amplifier forms a thin film on the equipment, upon which the leaking gas must pass before escaping to atmosphere. The escaping gas produces small bubbles in the liquid film, which burst with a “soda-like” effect. The bursting of these bubbles produces low-decibel sound waves that are heard as a crackling effect through the Ultraprobes’ headphones. After hearing the sound from bubbles crackling, the employee doing the inspection knows to mark the location for leak repair.

The application of this technology was particularly effective on a 35-year old mini-bus in an outdoor environment, which had welded aluminum connections that were prone to become porous with tiny pinholes during extremely cold conditions.

The company noted that, since 2009 when it first started using the Ultraprobe for ultrasonic leak detection, its SF6 emissions have decreased by approximately 55%.

2009 Awards for Global Climate Protection Efforts

- Arizona Public Service of Phoenix, Arizona

Arizona Public Service (APS) of Phoenix, Arizona, has adopted improved handling and maintenance practices and increased SF6 recycling, which prevented more than 100,000 pounds of SF6 from entering the atmosphere between 2001 and 2007. These reductions are the equivalent of annual emissions from over 200,000 cars. In recent years, APS has achieved substantial emissions reductions through an emissions reduction strategy focused on properly utilizing an SF6 recycling gas cart to reclaim, purify and reuse their SF6 gas during equipment service or repair. These recycling efforts have significantly reduced the amount of SF6 gas purchases required and have reduced SF6 leakage associated with maintenance activities.

Other important components of APS's emission reduction strategy include repairing 14 high-priority breakers during the 2006 and 2007 reporting years and using a laser imaging camera to identify the exact location of leaks. Lastly, APS has played an extremely valuable role in sharing knowledge about SF6 emission reduction strategies by hosting site visits for a previous Partnership conference as well as this year's workshop.

APS's active commitment to facilitating the exchange of information has been vital to the success of these events and has contributed to the achievement of SF6 emission reductions across the Partnership.

- Consolidated Edison Company of New York

By replacing equipment and improving leak detection, Consolidated Edison Company of New York has prevented over 670,000 pounds of SF6 from entering the atmosphere between 1999 and 2007, equivalent to the annual emissions from 1.3 million cars. Consolidated Edison is a Charter Partner to the program, which was launched in 1999.

In recent years, Con Edison has embarked on an aggressive equipment repair and replacement strategy that resulted in the replacement of over 20 circuit breakers during the 2006 and 2007 reporting years. Furthermore, Con Edison has been a leader in using innovative technologies to reduce SF6 emissions, including a laser imaging camera developed in conjunction with the Electric Power Research Institute (EPRI) to identify leaky equipment and a new sealing method to seal leaks on flanges under pressure.

The lessons that Con Edison has learned from implementing new technologies were used to provide guidance for EPRI's SF6 Gas Handling Tutorial and to provide technical assistance to EPRI's SF6 task force. The company has also developed an on-the-job training course for handling SF6 gas, which is distributed to all field employees who handle SF6. Con Edison's transmission infrastructure presents a challenging scenario for limiting SF6 gas emissions. But with a consistent focus on utilizing the best and newest emission reduction strategies, Con Edison has achieved large SF6 emission reductions and has made significant contributions to our knowledge of practical mitigation options.

2006 Awards for Global Climate Protection Efforts

- Southern California Edison, Irvine, California

Dina Kruger and Jerome Blackman, EPA, with the Electric Power Systems Partner Awardees from Southern California Edison, Howard Gollay and Alex Salinas.Southern California Edison (SCE) received an award from the EPA Sulfur Hexafluoride (SF6) Emission Reduction Partnership at its 4th International Conference on SF6 and the Environment. SCE has been instrumental in sharing information with EPA, electric power associations and other power companies regarding SF6 management practices and emission reduction activities.

Dina Kruger and Jerome Blackman, EPA, with the Electric Power Systems Partner Awardees from Southern California Edison, Howard Gollay and Alex Salinas.Southern California Edison (SCE) received an award from the EPA Sulfur Hexafluoride (SF6) Emission Reduction Partnership at its 4th International Conference on SF6 and the Environment. SCE has been instrumental in sharing information with EPA, electric power associations and other power companies regarding SF6 management practices and emission reduction activities.SCE, an Irvine, California based electric company, joined the SF6 Emission Reduction Partnership for Electric Power Systems in March 2001. The company has since reduced its SF6 emissions by 32 percent. SCE’s SF6 emission rate is lower than the overall average of 8 percent for the Partnership, which is remarkable given the company’s size and the amount of SF6 equipment it maintains.