Federal Technology Transfer Act Success Stories

Successful Federal Technology Transfer Act (FTTA) partnerships demonstrate the many advantages of technology transfer and collaboration. EPA and partner organizations create valuable and applicable technologies for the marketplace.

External partners can use EPA’s high-quality research to develop new products and collaborate on additional research. EPA benefits from outside expertise, product development, and funding to develop solutions that can be rapidly applied to environmental problems. The public benefits from these agreements because new technologies reach the market quickly. Overall, successful FTTA partnerships further the goal of a cleaner, healthier environment.

- FLC Interagency Partnership Award for Post-Fire Assessment Tool

BAER Team Members - Photo Credit: Scott Sheppard

BAER Team Members - Photo Credit: Scott Sheppard

The Federal Laboratory Consortium (FLC) for Technology Transfer awarded the 2018 Interagency Partnership Award to the Environmental Protection Agency, in conjunction with USDA’s Agricultural Research Service, National Interagency Fire Center (NIFC), Bureau of Land Management, National Weather Service (NWS) and the University of Arizona. Scientists from all parties transferred the Automated Geospatial Watershed Assessment (AGWA) tool to NIFC member agencies to speed the completion of post-fire watershed assessment. The tool identifies and targets treatments and resources where they are most needed to reduce threats of destructive surface erosion, flooding, and property loss. Functionality has been incorporated into the Automated Geospatial Watershed Assessment Tool (AGWA) to assess the impacts of wildland fire on runoff and erosion.

AGWA is a GIS interface jointly developed by Phillip Guertin, Professor, University of Arizona; David C. Goodrich, Research Hydraulic Engineer, Agricultural Research Service; Shea Burns, Senior Research Specialist, University of Arizona; B. Scott Sheppard, Hydrologist, Tongass National Forest; Jane Barlow, GIS Analyst, Tucson Water; Thomas T.J. Clifford, Assistant Field Manager, Boise District Office; Carl Unkrich, Hydrologist, Agricultural Research Service; and William G. Kepner Research, Ecologist, U.S. Environmental Protection Agency. Through an intuitive interface the user selects an outlet from which AGWA delineates and discretizes the watershed using a Digital Elevation Model (DEM). The watershed model elements are then intersected with terrain, soils, and land cover data layers to derive the requisite model input parameters. Based on a small sample of pre- and post-fire rainfall-runoff data, a method was developed to adjust model parameters as a function of the pre-fire vegetation cover and fire severity maps.

A pioneering aspect of the technology transfer process involved embedding AGWA team members with Interagency Burned Area Emergency Response (BAER) teams on actual post-wildfire deployments. This allowed AGWA team members to increase their understanding of BAER workflow, information requests, decision processes, and reporting requirements. Between fire seasons, the AGWA team attended BAER pre-season workshops and taught a two-day AGWA training course with computer tutorials derived from prior wildfires. Feedback during the training sessions prioritized improvements that would further enhance AGWA for BAER team use. Thus far, AGWA has been downloaded over 15,600 times and can track usage across 178 countries on six continents and 5,281 cities. In another advantageous application of AGWA’s technology transfer, BAER leaders requested the assistance of the NWS with post-fire flash flood warnings. As a result, the AGWA/KINEROS2 model has been evaluated in seven NWS Weather Forecast Offices for real-time flash flood forecasting in 47 watersheds. All agencies involved in this effort embraced the technology transfer of AGWA through in-kind support, extensive interagency communication, and a passion to improve the nation’s response to the increased number of wildfires.

- Removing Ammonia from Drinking Water

Full-scale treatment system for oxidizing ammonia in drinking water Under the Safe Drinking Water Act, the Environmental Protection Agency (EPA) sets maximum contaminant levels that apply at the entry point into a distribution system rather than within the distribution system. Because monitoring contaminants is not normally conducted at the consumer’s tap, their presence can go undetected. If nitrification resulting from elevated ammonia levels in the source water occurs in the distribution system, elevated levels of nitrites and nitrate can reach the consumer.

Full-scale treatment system for oxidizing ammonia in drinking water Under the Safe Drinking Water Act, the Environmental Protection Agency (EPA) sets maximum contaminant levels that apply at the entry point into a distribution system rather than within the distribution system. Because monitoring contaminants is not normally conducted at the consumer’s tap, their presence can go undetected. If nitrification resulting from elevated ammonia levels in the source water occurs in the distribution system, elevated levels of nitrites and nitrate can reach the consumer.EPA designed and patented a technology to oxidize ammonia in drinking water before it reaches the distribution system, which avoids nitrification in the distribution system and other problems associated with the presence of ammonia. Since 2014, EPA’s National Risk Management Research Laboratory in Cincinnati, Ohio has partnered with AdEdge Water Technologies, LLC, of Duluth, Georgia, to further develop and commercialize the technology. Together, the EPA and AdEdge have collaborated to evaluate a two-stage aerobic treatment system for the removal of ammonia from drinking water. The treatment approach enhances the natural nitrification process during which, in the presence of oxygen, ammonia is converted to nitrite and then to nitrate. AdEdge holds a license of this technology and has marketed it as NoMonia, an innovative water treatment technology to remove ammonia, arsenic, iron, and manganese.

Many regions in the United States have excessive ammonia in groundwater from natural and agricultural sources. While ammonia in water does not pose a direct health concern, nitrification of significant amounts of ammonia may. Ammonia in water may create high chlorine demand for disinfection (if addressed by breakpoint chlorination). In the presence of total organic carbon, excess chlorine is a concern because it creates a disinfection by-product. High ammonia levels may interfere with the removal of other regulated contaminants such as arsenic, iron, and manganese. Ammonia in raw water may also result in nitrification in the distribution systems, and can cause corrosion, poor taste, and odor issues. Legacy treatment approaches for the removal of ammonia, such as ion exchange or reverse osmosis, generate high total dissolved solids (TDS) wastewater, a challenge that the NoMonia biological treatment process eliminates. As a product of the collaboration, a pilot demonstration was concluded in August 2017 in Gilbert, Iowa. The pilot demonstration provided the city, AdEdge and the EPA with multiple data sets to further establish critical design parameters of a full-scale treatment system. AdEdge is working with the community and their engineer firm to design a full-scale system based on the pilot results. Additional pilot demonstrations are anticipated in other areas, such as Illinois and Minnesota. The technology is available for licensing by additional companies.

- Reducing Children’s Exposure to Lead in Drinking Water

Water is essential to our lives and plays an important role in overall health. Accessible drinking water in schools and childcare facilities, where children spend a significant portion of their days, offers children a healthy drinking option. As we encourage our children to drink tap water, we need to ensure that the water they are drinking is safe.

EPA partnered with the W.K. Kellogg Foundation and Calhoun County, Mich., in a three-year project to reduce children’s exposure to lead in drinking water. The project, a Cooperative Research and Development Agreement (CRADA), involved multiple EPA offices. It was spearheaded by EPA’s Office of Water (OW), and supported by the Office of Research and Development (ORD), as well as numerous regional laboratories.

Testing tap water at schools or childcare facilities is the best way to know whether the facility’s water might have elevated levels of lead, for which children are at a particular risk of exposure.

Under the CRADA, the Calhoun County Public Health Department tested for lead in drinking water at approximately 75 facilities in the Calhoun County area. EPA’s OW and ORD provided technical assistance; and Regions 2, 3, 5, 6, 7, 9, and 10 conducted the analyses on the samples collected. The W.K. Kellogg Foundation provided financial support to Calhoun County for this effort.

Where unsafe lead levels were discovered, various technologies were implemented to remediate or mitigate the contamination. Nine schools or childcare facilities had outlets with lead levels above 20 ppb. The remediation employed included flushing and plumbing component replacement. ORD and OW assisted with identification of the appropriate remediation technology.

The data collected for this project provide valuable information on lead variability in schools and childcare facilities, before and after remediation. This data will help inform other schools across the nation about the frequency with which they should conduct lead testing. The project highlights cost-effective remediation practices and technologies that schools can implement to reduce lead in drinking water. It also provides valuable cost information on these technologies. This helps EPA and communities in better understanding the costs involved with this type of lead remediation. And overall, the project resulted in a decrease in lead exposure to children and staff at the facilities where these children spend a significant portion of their day.

In 2005, EPA announced the Drinking Water Lead Reduction Plan, which outlined actions the agency would undertake in response to its review of the Lead and Copper Rule. Under the plan, the agency stated it would continue to work with partners to promote research in key areas and efforts to protect children from lead. This CRADA allowed EPA to further these goals, and helped Calhoun County make its schools and childcare facilities healthier.

- Bringing Portable Water Treatment to Hurricane-Impacted Puerto Rico

First Responder Sets up Training on Mini Water Treatment Unit

First Responder Sets up Training on Mini Water Treatment Unit

Photo Courtesy of Alton Strupp of Courier Journal, Louisville, KY

Delivering safe drinking water is a concern around the world, but it is paramount to environmental and human health in developing countries and in disaster-ravaged areas. EPA has a decades long mandate to protect drinking water sources and to ensure that communities are delivering the highest quality water possible to their customers.

In 2017, hurricanes Harvey, Irma, and Maria significantly affected Texas, Florida, Puerto Rico, and the U.S. Virgin Islands. These natural disasters highlighted the importance of providing safe drinking water to those impacted by the storm. Hurricane Maria impacted Puerto Rico particularly severely due to the complete power loss and disabling of nearly all the drinking water utilities. In addition to physical damage to the utilities, the storm also caused potentially harmful pollutants to enter into source waters.

EPA has had a long-standing interest in supporting communities in their efforts to rebound from man-made and natural disasters. In particular, EPA has focused on addressing the serious water contamination implications of natural disasters. This focus ensures that a ready supply of safe drinking water is available until the water utilities are up and running again.

The Agency realized there is a need for turn-key, robust water treatment systems that can be transported and quickly set up to provide safe drinking water. In 2015, the EPA entered into a Cooperative Research and Development Agreement (CRADA) with WaterStep (Louisville, KY). EPA established this CRADA to develop an affordable, modular, mobile water treatment technology system. The system is specifically designed for use in rural areas, in developing countries, and in emergency response efforts. EPA’s role in the CRADA has been to provide technical assistance and logistical and environmental sampling and analysis support. WaterStep took the lead in designing the mobile treatment cart and provided the engineering and fabrication.

Under this CRADA, the partners designed the Emergency Mobile Water System and built prototypes. WaterStep realized that it could help the people suffering from the lack of potable drinking water. Within days after Hurricane Maria passed through, it deployed multiple Mini Water Treatment Units (Mini) (a version of the Emergency Mobile Water System) in Puerto Rico. These units are a rapid-deployment option and provide system redundancy for disaster relief organizations, water utilities, or others responsible for providing safe water.

Each Mini includes everything needed for quick assembly and operation, and can deliver safe drinking water within 30 minutes of set-up. Each unit has a solar panel and a chlorine generator. Even as the country continues to restore power to utilities, the water treatment units can provide up to 10,000 gallons of drinking water per day. WaterStep joined with the National Puerto Rico Leadership Council Education Fund to install the Mini treatment units at 78 Puerto Rican municipalities and train local officials and emergency response workers to use them. This collaboration has had a significant impact on the communities and the people of Puerto Rico.

- EPA Evaluates Effectiveness of Arsenic Water Treatment Systems for Small Communities

After a 2001 lowering of the arsenic drinking water standard, EPA researchers at the National Risk Management Research Laboratory (NRMRL) engaged in a series of Cooperative Research and Development Agreements (CRADAs) with small communities. The goal of the CRADAs was to assist with selection and installation of arsenic mitigation technologies. Additionally, there was the benefit of analyzing the capital and operational cost and real-world effectiveness of these systems. During the course of these projects, arsenic treatment technologies were installed at 50 different sites with detailed cost and performance reports published on each system. Over half of the sites utilized adsorptive media systems with 11 different media products. The remainder of the systems were split among four other types of treatment technologies. Flows of the individual systems ranged from 10 gpm to 640 gpm.

In recent years, the EPA researchers followed up with these communities to check on the effectiveness and longevity of the systems. These communities include schools, housing developments, and small towns. About 90% of the systems are still in operation after 8-10 years. The researchers found that the ion exchange systems had the most problems and required the greatest operational attention. In general, iron removal systems had the fewest performance and operational problems. The majority of adsorptive media systems, which require the replacement of the adsorptive media when exhausted, continue to operate with about half having switched to a better performing (life) media product.

The value of these CRADAs lies in EPA’s expertise to assist small communities with treating arsenic levels above the standard by selecting appropriate arsenic water treatment systems, and assisting with their installation. EPA also gained valuable information regarding the stability and effectiveness of these various technologies. A decade after their installation, EPA is encouraged that 90% of the systems are still operating, bringing safer drinking water to these communities. Reports published after these projects have also been important to other communities and state agencies in selecting the best treatment system to achieve compliance of the arsenic rule.

- Removing Mercury, Arsenic and Other Metals from Contaminated Water Streams

Sorbster media for removal of mercury, arsenic, and other metals from a contaminated waste stream.

Sorbster media for removal of mercury, arsenic, and other metals from a contaminated waste stream.MAR Systems and EPA partnered under a Cooperative Research and Development Agreement (CRADA) to investigate the reuse of spent catalysts from the Claus process. The Claus process is a final polishing step for light hydrocarbons to remove trace amounts of sulfur. The spent Claus catalysts have historically been disposed.

The researchers used the spent Claus catalysts to remove soluble metal contaminants from contaminated water streams.

The collaboration has continued through an exclusive license to MAR Systems for commercialization. The technology has been developed into a media, called Sorbster. MAR Systems manufactures Sorbster and uses it to treat the following in waste water streams at pH 3-12:

- Mercury

- Selenium

- Arsenic

- Other metals

This includes treatment of contaminated water streams, ground and surface water, and industrial waste streams. Benefits of the technology include:

- Ability to achieve Clean Water standards

- Cost-effective design

- Simplicity

- Reliability

This technology is now commercially available. MAR Systems has established a number of demonstration projects with small units (less than 10 gallons per minute). They also installed a commercial system treating 250 gallons per minute at a chemical manufacturing facility.

The future direction is to optimize the technology for additional metals removal. The partners are also investigating metals removal of vapor or stack emissions, as well as metals removal from waste water associated with hydraulic fracturing.

- Gathering Data on Emissions of Large Vehicles

Technology to capture emissions data was temporarily installed on vehicles for this study.

Technology to capture emissions data was temporarily installed on vehicles for this study.Mobile sources contribute significantly to concentrations of air contaminants, including particulate matter. EPA’s National Vehicle and Fuel Emissions Laboratory collaborated with the Houston-Galveston, Texas area to investigate heavy-duty vehicle pollutants.

The partners studied heavy-duty drayage vehicles used at ports to determine their emissions contribution. Over 40 vehicles were studied in-depth for both emissions as well as activities.

EPA signed a Cooperative Research and Development Agreement (CRADA) with the Houston-Galveston Area Council, in cooperation with the Texas Commission on Environmental Quality. The collaborators also worked with the Port Authority of Houston to improve data on the amount of time vehicles were in the port area.

EPA reviewed and analyzed emission data on the heavy-duty vehicles to verify EPA’s emission modeling system - Motor Vehicle Emission Simulator (MOVES). This system captures emission factors for model year (MY)1990 through MY2006. EPA will use the data collected in the CRADA to update the latest version of MOVES.

EPA analyzed over 18 months of terminal visit data from two terminals within the Port of Houston. The average trip length (defined by “key on/off”) was 10 miles in length for 66% of all trips. EPA found that very few trucks were visiting these port terminals on a regular basis and were doing other local short-hauling work.

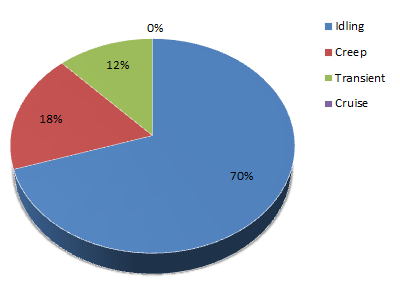

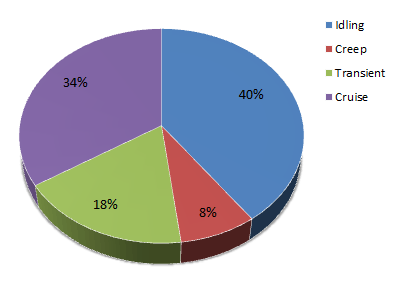

The partners analyzed data on the vehicle operating modes between port and non-port activity and found the results very consistent over four port terminals visited during this test program. They considered idle, creep, transient, and cruise for the vehicle operating modes.

The results from the four ports showed: The results from non-port activities showed:

Idling: 70%; Creep: 18%; Transient: 12%; Cruise: 0%

Idling: 40%; Creep: 8%; Transient: 18%; Cruise: 34%

Port visits lasted approximately 48 minutes. Most of the trucks visited in the morning hours and during the work week. These analyses help the Houston-Galveston Area Council gain a clearer picture of the contributions of port vehicles to overall air emissions.

EPA established a more thorough, statistically accurate sampling methodology for heavy-duty vehicles during this project. Other geographic locations with heavy-duty vehicles and port usage could apply this improved methodology to determine emissions contributions to the local area.

As EPA’s models are enhanced to include more real-world data, states can better anticipate how they will comply with National Ambient Air Quality Standards (NAAQS).

- EPA and Industry Partners Apply Hybrid Technology to Port Vehicles

EPA and industry partners apply hybrid vehicle technology as part of EPA’s national clean diesel campaign’s clean ports program.

EPA and industry partners apply hybrid vehicle technology as part of EPA’s national clean diesel campaign’s clean ports program.EPA and its industry partners developed a leading-edge, pollution-saving truck for transferring cargo containers. They applied EPA’s patented series hydraulic hybrid vehicle (HHV) technology to the heavy-duty truck.

EPA and its partners then moved this series hydraulic hybrid yard hostler into field testing at port terminals in the U.S. Hostlers are large, off-road vehicles used to transfer cargo containers at:

- Marine ports

- Rail yards

- Warehouses

- Distribution centers

The trucks spend about half of their time idling and contribute to air pollution generated in ports throughout the world.

EPA’s unique series HHV power train efficiently recovers, stores and reuses braking power. At the same time, the technology significantly reduces idling and optimizes engine operation to use less fuel and reduce air pollution.

HHV technology has been demonstrated and field tested in a number of vehicles, including package delivery vehicles. EPA believes this vehicle design can improve the efficiency of the yard hostler operation by 50-60%.

EPA program collaborators included:

- The National Clean Diesel Campaign (NCDC) and its Clean Ports USA

- Clean Automotive Technology

- Office of International Affairs

- EPA Region 2 (New York and New Jersey)

Industry technical partners included:

- APM Terminals

- Parker-Hannifin

- Kalmar Industries

- FEV Inc.

- R. H. Sheppard Co Inc.

- Webasto

- The Port Authority of New York

- The New Jersey Department of Environmental Protection

Reducing emissions from diesel engines is one of the most important air quality challenges facing the country today. NCDC includes innovative programs to address the millions of diesel engines already in use as well as regulatory programs to address new diesel engines.

EPA’s Clean Automotive Technology Program conducts innovative research primarily to:

- Achieve ultra-low pollution emissions

- Reduce greenhouse gases

- Increase fuel efficiency

By developing cost-effective technologies, the Clean Automotive Technology Program also encourages manufacturers to produce cleaner and more fuel-efficient vehicles.

- National Clean Diesel Campaign (NCDC)

- NCDC's Ports & Marine webpage

- EPA's ports initiative

- EPA's Clean Automotive Technology program Search EPA Archive

- EPA's ToxCast Program Prioritizes Toxicity Testing of Environmental Chemicals

In 2007 EPA launched ToxCast™ to develop a cost-effective approach for prioritizing toxicity testing of many chemicals in a short time period. ToxCast™ uses data from high throughput screening (HTS) bioassays developed in the pharmaceutical industry. Using that data, ToxCast™ builds computational models to forecast the potential human toxicity of chemicals.

These hazard predictions provide EPA regulatory programs with science-based information that is helpful in prioritizing chemicals for more detailed toxicological evaluations. It also leads to more efficient use of animal testing.

When EPA launched ToxCast™ in 2007, it announced collaborative opportunities to facilitate and expand the development of ToxCast™. In Phase 1 of the ToxCast™ program alone, EPA executed over 20 Federal Technology Transfer Act (FTTA) agreements.

Working with these partners expands high-throughput bioassay data results on over 300 well-characterized chemicals in over 400 HTS endpoints. Most of these chemicals are pesticides. These endpoints include:

- Biochemical assays of protein function.

- Cell-based transcriptional reporter assays.

- Multi-cell interaction assays.

- Transcriptomics on primary cell cultures.

- Developmental assays in zebrafish embryos.

Almost all of the compounds examined in Phase 1 of ToxCast™ have been tested in traditional toxicology tests, including:

- Developmental toxicity

- Multi-generational studies

- Sub-chronic and chronic rodent bioassays

ToxRefDB, a relational database created to house this information, will contain nearly $1 billion worth of toxicity studies in animals when completed.

EPA will screen additional compounds representing broader chemical structure and use classes during the second phase of ToxCast™. This allows EPA to evaluate the predictive bioactivity signatures developed in Phase 1.

ToxCast™ will provide EPA regulatory programs with an efficient tool for rapidly and efficiently screening compounds and prioritizing further toxicity testing. EPA's National Center for Computational Toxicology (NCCT) continues to expand ToxCast™ with information shared through FTTA agreements.

- DNA-Based Innovation To Identify Molds and Bacteria

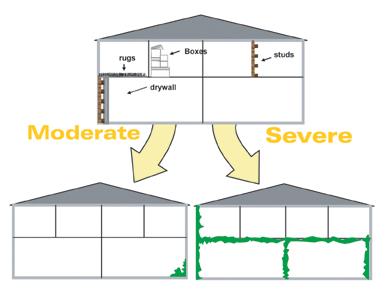

Testing for molds with EPA’s DNA-based technology may show if a structure is contaminated with molds and fungi, and to what degree.

Testing for molds with EPA’s DNA-based technology may show if a structure is contaminated with molds and fungi, and to what degree.Mold (i.e., fungi) in homes, schools and businesses can cause numerous health problems in the United States. EPA researchers developed a new technology to identify these mold-related problems quickly and accurately. This can lead to more effective diagnosis and treatment of related illnesses. Use of this technology may also prevent disease occurrence.

EPA’s DNA-based process can identify and quantify more than 130 species of toxic molds and potentially pathogenic fungi in the environment. Fungi and bacteria cause or contribute to many health problems, including:

- Infections

- Gastroenteritis

- Ulcers

- Asthma

- Allergies

- Sinusitis

EPA's invention may have applications in research related to therapeutics and diagnostics for these illnesses. Additionally, this technology can be used to:

- Determine whether an environment is abnormally contaminated with mold.

- Test homes and water for pathogenic molds.

- Monitor hospitals to prevent nosocomial mold infections.

- Rapidly diagnose mold infections so that treatment can begin earlier.

- Monitor food and drugs for mold contamination.

- Measure the risk for mold associated with allergic and asthmatic disease.

- Diagnose chronic rhinosinusitis.

- Monitor crops for mold pathogens in an integrated pest management program, thereby reducing the use of pesticides.

This method provides real-time results that are more accurate and less time consuming than current technologies. EPA licensed this technology to several commercial laboratories in the U.S. and the European Union to provide diagnostic services for their clients.

- Identifying Wood-Fired Heaters with Lowest Emissions

EPA and NYSERDA tested residential wood-fired heaters with various fuels to determine emissions.

EPA and NYSERDA tested residential wood-fired heaters with various fuels to determine emissions.EPA and the New York State Energy Research and Development Authority (NYSERDA) conducted a research project to evaluate wood-fired residential hydronic heater technologies. Using a Cooperative Research and Development Agreement (CRADA) the partners characterized:

- Emissions

- Health impacts

- Energy market penetration

EPA and NYSERDA looked at several types of residential wood-burning technologies. They evaluated and characterized the technologies for a variety of emissions under realistic, homeowner operation scenarios. The partners used EPA's combustion laboratories in Research Triangle Park, North Carolina for the research. They evaluated the following types of technologies:

- A common hydronic heater

- A high-efficiency pellet heater

- A unit with thermal storage

They tested three fuel types:

- Red oak

- White pine

- Red oak with supplementary household refuse

EPA and NYSERDA measured:

- Emissions of particulate matter

- Elemental carbon

- Carbon monoxide

- Polycyclic aromatic hydrocarbons (PAHs)

- Volatile organic compounds (VOCs)

- Semi-volatile organic compounds (SVOCs)

- Polychlorinated dibenzodioxins/dibenzofurans (PCDDs/Fs)

The partners completed an analysis of energy and market impacts of hydronic heaters for the State of New York. Lastly, they evaluated the health effects of hydronic heater emissions with an exposure study for pulmonary and systemic biomarkers of injury and inflammation.

Results of this study will assist New York in developing a high-efficiency biomass heating market of technologies with lower emissions. These results will also help EPA as it sets New Source Performance Standards for biomass-fired hydronic heaters.

EPA and NYSERDA have published several documents on the results of this study. Additionally, New York State is conducting follow-up research.