Portable Device to Concentrate Water Samples for Microorganism Analysis

Inventors: Alan Lindquist, Vicente Gallardo, Michael V. Carpenter, Lyle G. Roybal

Owned by EPA

Patent Information from the U.S. Patent and Trademark Office website Exit

Link to Video on Water Concentrator Technology Exit

Federal Technology Transfer Act (FTTA) staff: Contact us if you are interested in learning more about how to license this technology.

Summary of the Technology

The transportation and handling of a large volume of potentially contaminated water is a safety concern for the transporters, laboratory personnel, and the public. To improve upon this situation, EPA teamed up with the Department of Energy’s Idaho National Laboratory (INL) to develop a rugged and automated field deployable sample concentration (ultrafiltration) device. The device significantly reduces the sample volume by concentrating the microorganisms contained in a large sample into a small volume of water. The device can concentrate the microbes contained in a 26-gallon sample into less than 2 cups of water, often in under an hour. Following concentration, the smaller, concentrated sample can be more easily and safely transported to a laboratory.

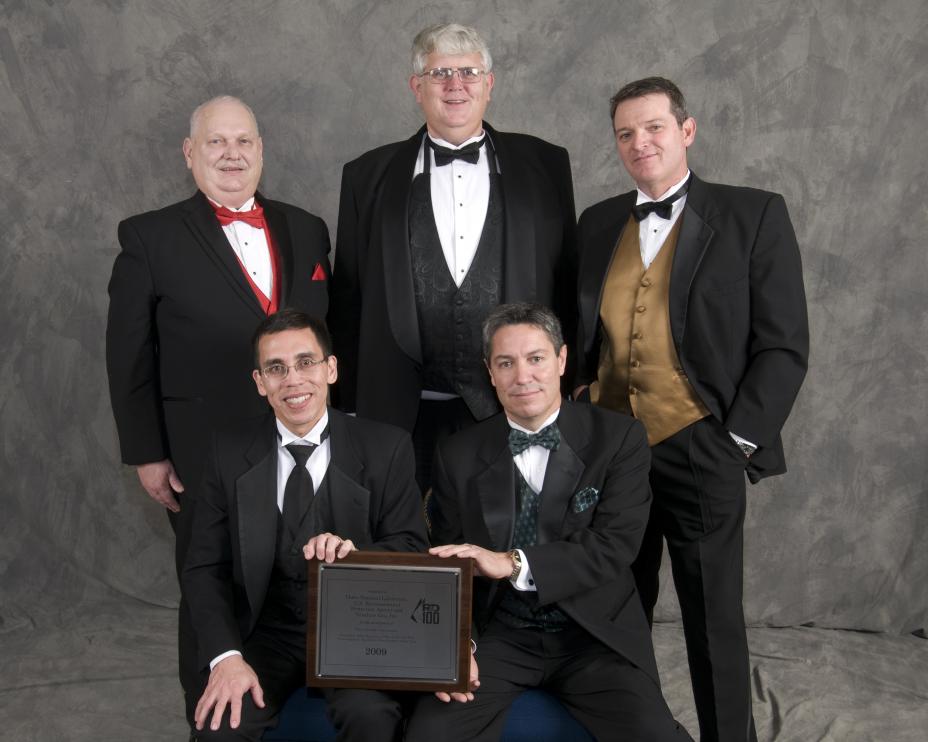

For the development of this filtration device, EPA and INL researchers received a 2009 R&D 100 Award from R&D Magazine. Each year, the editors of R&D Magazine bestow the prestigious R&D 100 Award to help new products compete in the marketplace. As stated by R&D Magazine, “the winning of an R&D 100 Award provides a mark of excellence known to industry, government, and academia as proof that the product is one of the most innovative ideas of the year”.

Background

The possibility of terrorists or criminals intentionally contaminating drinking water with pathogenic microorganisms is a significant public health concern. This concern has given rise to the need to rapidly and effectively sample water to detect small concentrations of potentially dangerous microorganisms. Detection of low concentrations of microorganisms in water necessitates a large volume (i.e., 100 liters or 26 gallons) water sample be taken. The larger the sample, the greater likelihood of capturing microorganisms present at low levels. The conventional practice has been to transport the large volume sample to a laboratory for concentration and analysis. This can be cumbersome for lab and field personnel, and the transport of a large volume sample that may contain a biological hazard can be prohibitively expensive.

How the Technology is Different

Using a computer controlled system, this ultrafiltration device automates the process of concentrating a water sample and can be operated in the field. The system was also designed to reduce human exposure to potentially contaminated water and to generate samples that are appropriate for the analyses of several types of microorganisms. The underlying technology has been tested by several laboratories.

The ultrafiltration device:

- Reduces sample collection and concentration time and cost – Sample concentration processes are automated, which reduces the time it takes to determine pathogen concentration. Because only a concentrated sample is shipped to a laboratory, the cost of transport is less. A one hundred liter water sample can often be processed and concentrated in about an hour.

- Improves accuracy and consistency – By using a large sample volume, analytical sensitivities may be improved by as much as 250 percent over smaller volume assays. Concentrated samples help ensure that low concentrations of microorganisms are accurately identified. The automation of processes that were previously performed manually in the laboratory should help improve the consistency of sample preparation.

- Requires minimal setup and training

- Allows for real-time monitoring – The computer screen provides a virtual display of the filtration process, allowing operators to monitor the status and quickly respond to operational issues during sampling.

- Eliminates cross-contamination – All device parts that come in contact with the sample water (e.g., tubing, fittings, pressure transducer) are single use items. This ensures that there is no cross-contamination between samples. The device includes quick disconnects for sample removal.

- Increased safety – The shipment and handling of a small water sample, compared with a high volume sample, is less likely to result in spillage, which decreases risk to the transporters, laboratory personnel and general public.

The approximate dimensions of the ultrafiltration device are 31 x 20 x 16 inches (795 x 518 x 393 millimeters), which allows it to fit into the trunk of a car. It consists of a pump, valves, sensors, electronic controls, a hollow fiber filter cartridge and a sample bottle. The device is controlled by software that can be installed on a personal computer. The device works by pumping water through a filter, while maintaining 10 to 25 pounds per square inch pressure difference between the filter inlet and outlet. This pressure difference forces the majority of the water to be discarded through a hollow fiber filter, while the microorganisms remain suspended in the concentrated sample.

Additional Uses

The ultrafiltration device could be used by water utilities during their routine regulatory compliance sampling. This routine sampling includes testing for several different microorganisms in drinking water. The ultrafiltration device may also be useful for sampling:

- Bilge water on shipping vessels

- Process control liquids from the brewing and pharmaceutical industries

- Surface water for environmental studies

- Decontamination water from cleanup areas.

Although not yet confirmed, the ultrafiltration device might be useful in concentrating samples for large molecular weight toxins such as ricin, as well as yeasts, fungi, viruses, protozoa and helminths, which are targeted pathogens in EPA’s new water reuse guidelines.