Bioreactor Landfills

- What is a Bioreactor Landfill?

- Unique Features to Bioreactors

- Potential Advantages of Bioreactor Landfills

- Special Considerations for Bioreactor Landfills

- Current EPA Bioreactor Research

- Bioreactor Efforts within EPA

- Additional Bioreactor Projects and Information

What is a Bioreactor Landfill?

A bioreactor landfill is a municipal solid waste landfill (MSWLF) in which liquids are added to help bacteria break down the waste. The increase in waste degradation and stabilization is accomplished through the addition of liquid and air to enhance microbial processes. This bioreactor concept differs from the traditional “dry tomb” municipal landfill approach.

Types of Bioreactor Landfills

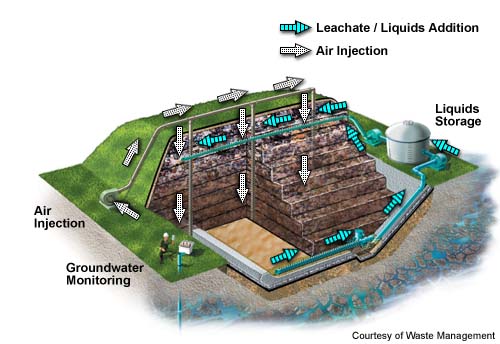

- Aerobic - In an aerobic bioreactor landfill, leachate is removed from the bottom layer, piped to liquids storage tanks, and re-circulated into the landfill in a controlled manner. Air is injected into the waste mass using vertical or horizontal wells to promote aerobic activity and accelerate waste stabilization.

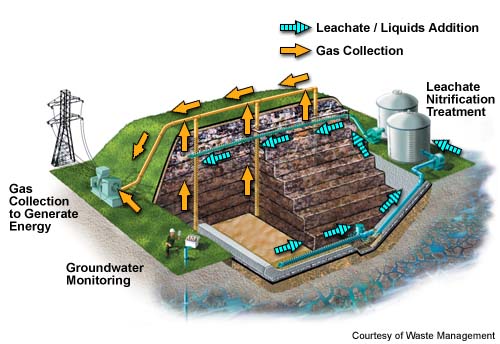

- Anaerobic - In an anaerobic bioreactor landfill, moisture is added to the waste mass in the form of re-circulated leachate and other sources to obtain optimal moisture levels. Biodegradation occurs in the absence of oxygen (anaerobically) and produces landfill gas. Landfill gas - primarily methane - can be captured to minimize greenhouse gas emissions and can be used for energy projects.

- Hybrid (Aerobic-Anaerobic) - The hybrid bioreactor landfill accelerates waste degradation by employing a sequential aerobic-anaerobic treatment to rapidly degrade organics in the upper sections of the landfill and collect gas from lower sections. Operation as a hybrid results in the earlier onset of methanogenesis compared to aerobic landfills.

Unique Features to Bioreactors

The bioreactor accelerates the decomposition and stabilization of waste. At a minimum, leachate is injected into the bioreactor to stimulate the natural biodegradation process. Bioreactors often need other liquids such as storm water, wastewater, and wastewater treatment plant sludges to supplement leachate. This enhances the microbiological process by purposeful control of the moisture content, and differs from a landfill that simply recirculates leachate for liquids management. Landfills that simply recirculate leachate may not necessarily operate as optimized bioreactors.

Moisture content is the single most important factor that promotes the accelerated decomposition. The bioreactor technology relies on maintaining optimal moisture content near field capacity - approximately 35 to 65 percent - and adds liquids when it is necessary to maintain that percentage. The moisture content, combined with the biological action of naturally occurring microbes, decomposes the waste. The microbes can be either aerobic or anaerobic. A side effect of the bioreactor is that it produces landfill gas (LFG) like methane in an anaerobic unit at an earlier stage in the landfill’s life at an overall much higher rate of generation than traditional landfills.

Potential Advantages of Bioreactor Landfills

Decomposition and biological stabilization of the waste in a bioreactor landfill can occur in a much shorter time than in a traditional “dry tomb” landfill. This can provide a potential decrease in long-term environmental risks and landfill operating and post-closure costs. Potential advantages of bioreactors include the following:

- Decomposition and biological stabilization in years versus decades in “dry tombs”

- Lower waste toxicity and mobility due to both aerobic and anaerobic conditions

- Reduced leachate disposal costs

- A 15 to 30 percent gain in landfill space due to an increase in density of waste mass

- Significant increased LFG generation that, when captured, can be used for energy use onsite or sold

- Reduced post-closure care

Due to degradation of organics and the sequestration of inorganics, research has shown that municipal solid waste can be rapidly degraded and made less hazardous by enhancing and controlling the moisture within the landfill under aerobic and/or anaerobic conditions. Leachate quality in a bioreactor rapidly improves, which leads to reduced leachate disposal costs. Landfill volume may also decrease with the recovered airspace offering landfill operators the full operating life of the landfill.

LFG emitted by a bioreactor landfill consists primarily of methane and carbon dioxide, as well as lesser amounts of volatile organic chemicals and/or hazardous air pollutants. Research indicates that the operation of a bioreactor may generate LFG earlier in the process and at a higher rate than the traditional landfill. The bioreactor LFG is also generated over a shorter period of time, because the LFG emissions decline as the accelerated decomposition process depletes the source waste faster than in a traditional landfill. The net result appears to be that the bioreactor produces more LFG overall than the traditional landfill does.

Some studies indicate that the bioreactor increases the feasibility for cost effective LFG recovery, which could reduce fugitive emissions. This presents an opportunity for beneficial reuse of bioreactor LFG in energy recovery projects. The use of LFG in traditional and bioreactor landfills for energy applications is currently only about 10 percent of its potential use. The U.S. Department of Energy estimates that if the controlled bioreactor technology were applied to 50 percent of the waste currently being landfilled, it could provide over 270 billion cubic feet of methane a year. This is equivalent to one percent of the United States electrical needs.

Special Considerations for Bioreactor Landfills

Several considerations about bioreactor landfills must be examined and understood before EPA can identify specific bioreactor standards or recommend operating parameters. Bioreactor landfills generally are engineered systems that have higher initial capital costs and require additional monitoring and control during their operating life, but are expected to involve less monitoring over the duration of the post-closure period than conventional “dry tomb” landfills. Issues that need to be addressed during both design and operation of a bioreactor landfill include the following:

- Increased gas emissions

- Increased odors

- Physical instability of waste mass due to increased moisture and density

- Instability of liner systems

- Surface seeps

- Landfill fires

Current EPA Bioreactor Research

EPA and its state and industry partners are studying and conducting research and demonstrations on bioreactor landfills and other landfills, such as those that re-circulate leachate. EPA hopes to learn more about the possible effects of bioreactor operations and the costs that may be associated with them. The Agency is examining various aspects of bioreactor landfills to do the following:

- Assess the state-of-the-practice of bioreactor landfill design, operation, and maintenance

- Identify case studies of bioreactor landfill use, especially where data exist for comparison between traditional and bioreactor approaches

- Determine long-term monitoring needs for environmental compliance for groundwater, gas emissions, leachate quality, liner stability, physical stability and other factors to satisfy life-cycle integrity and economic viability concerns

- Exchange views, technical concerns and implementation concerns regarding both pending and planned regulations effecting landfills in general, and the regulatory framework to be developed for bioreactor landfills

- Examine the economic viability, impacts and benefits of bioreactor landfill implementation at full scale

- Identify and prioritize research and regulatory needs

EPA will need to collect data on the following information to make a determination regarding the benefits of bioreactors, as well as to understand the concerns associated with them:

- Alternative liner design/materials for leachate recirculation and bioreactor landfills

- Physical stability of the cover and bottom liner during and after operation

- Impacts of leachate quality, quantity and loading on the liner system

- Times and amounts of liquids it takes to reach field capacity

- Appropriate means for measuring field capacity

- Leachate recirculation and its effect on the rate and extent of landfill stabilization

- Stabilization measures

- Design, operation and performance specifications for bioreactors

- Rate, quantity and quality of gas generation

- Interim covers used after placement to accommodate anticipated settlement

- Daily and final cover performance

- Optimum moisture content and distribution methods

- Monitoring requirements

- Bioreactor technology impacts on capping, as well as current closure and post-closure requirements

Bioreactor Efforts within EPA

The following is a list of the bioreactor research studies, demonstrations and guidance efforts currently underway within EPA:

Project XL Bioreactor Landfill Pilots

Project XL (i.e., eXcellence and Leadership) is an EPA initiative, which began in 1995. The program provides limited regulatory flexibility for regulated entities to conduct pilot projects that demonstrate the ability to achieve superior environmental performance. The information and lessons learned from Project XL are being used to assist EPA in redesigning its current regulatory and policy-setting approaches. As of September 2001, 51 pilot experiments have been implemented. Of those being implemented in this innovative program, four landfill pilot projects have been approved to operate as bioreactors. These landfill pilot projects include the following locations:

- Buncombe County Landfill Project, North Carolina

- Maplewood Landfill and King George County Landfills, Virginia

- Yolo County Bioreactor Landfill, California

EPA will provide these facilities with regulatory flexibility that will allow them to recirculate leachate and other liquids over a municipal solid waste landfill (MSWLF) unit constructed with an alternative liner system. In turn, the designers of these bioreactor XL projects hope that, when implemented, the leachate recirculation/gas recovery landfill approach will provide superior environmental performance in a number of ways. This will include the following improvements:

- Enhanced groundwater protection

- Reduced landfill gas emissions by early installation and operation of gas collection and control systems

- Additional waste capacity and longer life of existing landfill cells, thereby reducing the need for new landfill sites

- Improved leachate quality and cleaner wastewater discharges

EPA expects to obtain significant information on bioreactor technology from these projects.

All of the Project XL bioreactor pilot projects will be evaluated on superior environmental performance, cost savings, paperwork reduction, sustainability, innovation, feasibility, and identification of monitoring and reporting methods. The results of the bioreactor XL projects may provide information to EPA on modifying specific criteria in the Title 40 of the Code of Federal Regulations (CFR) part 258 regulation.

Time Frame: The pilot demonstrations are expected to be completed according to the agreed upon duration for each individual project -between 2006 and 2026. The evaluations will be ongoing and will be completed shortly after each pilot is done.

EPA State-of-the-Practice Bioreactor Landfill Study

The purpose of the State-of-the-Practice Bioreactor Landfill Study is to compare data from bioreactor landfills with traditional dry landfills. This study will survey five operating bioreactor landfills and identify the regulatory, environmental and operating parameters of these landfills. The study will also help to begin identifying and evaluating best operating practices.

The study will assist EPA in determining long-term monitoring needs for environmental compliance with groundwater standards, gas emissions, leachate quality, liner stability, physical stability, and other factors to address life-cycle integrity and economic viability concerns. The information will assist owners and/or operators, as well as permit writers, to better operate and/or regulate bioreactor landfills. In addition, this study should lay the groundwork for the Agency to develop technical guidance and/or best practices for design, operation and permitting the bioreactor landfill.

Cooperative Research with Waste Management using a Cooperative Research and Development Agreement (CRADA)

EPA’s National Risk Management Research Laboratory is partnering with Waste Management, Inc. to conduct research on several large-scale bioreactor landfills looking at several variables. This work is being conducted through a Cooperative Research and Development Agreement. The purpose of this five-year, joint research effort is to collect sufficient information to determine the best operating practices to promote safe operation of bioreactor landfills.

The following images demonstrate the various design and operating features that are being studied:

Bioreactor Performance Report

EPA studied five bioreactor sites and investigated their performance. The following lists the specific parameters studied:

- leachate head on liner

- side slope stability

- settlement

- leachate collection

- gas collection, and

- prevention of fires

The Bioreactor Performance paper describes how leachate head maintenance, settlement, side slope stability, fire prevention and gas collection were designed to protect human health and the environment at the five sites.

Revision to the Research, Development and Demonstration (RD&D) Permits Rule for Municipal Solid Waste Landfills

On May 10, 2016, a final rule was published in the Federal Register revising the maximum permit term for Municipal Solid Waste Landfill (MSWLF) units operating under RD&D permits.

This final rule allows RD&D permits for municipal solid waste landfill bioreactors to be extended from 12 to up to 21 years. The rule allows directors of EPA approved state waste programs to increase the number of renewals for such permits from three to six.

Notice on Revisions to Address Liquids Management in Landfills

EPA is considering proposing changes to the current municipal solid waste landfill (MSWLF) regulations or possibly developing a separate set of regulations specific to wet and bioreactor landfills. Below is key information from Advanced Notice of Proposed Rulemaking (ANPRM):

- The premise of the ANPRM is that adding liquids to landfills may have benefits in contrast to dry tomb landfills.

- EPA data research suggests that adding liquids to MSWLFs may reduce environmental risks and increase economic benefits, provided that landfill gas (LFG) collection and leachate containment systems are in place.

- Environmental risk may be reduced through faster waste subsidence and stabilization, decreased need for transport and treatment of leachate, and a shorter time for post-closure care.

- Economic benefits may result from the accelerated generation of LFG for use as a renewable fuel, and reduced costs for leachate treatment and post-closure care.

The purpose of this ANPRM was to solicit data and information. EPA accepted comments through May 10, 2019, and is reviewing the comments. View the official version of the notice in the Federal Register.

Additional Bioreactor Projects and Information

For more information on bioreactors and bioreactor projects, click on the following links:

- Aerobic Landfill Technology Exit aerobic landfill technology provided by Environmental Control Systems, Inc.

- Yolo County Landfill Exit provides information which is piloting a bioreactor (wet cell) landfill operation, which increases the rate of waste decomposition and increases the rate of methane production for more efficient methane collection and use.