Renewable Natural Gas

On this page:

- Basic Information about Renewable Natural Gas (RNG)

- RNG Project Map

- Benefits

- Resources

- More Information on RNG

Basic Information about RNG

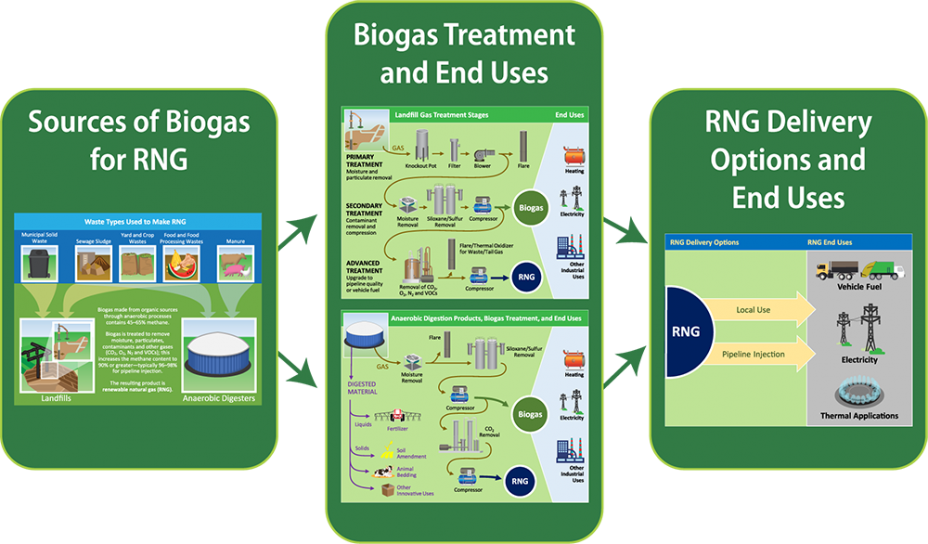

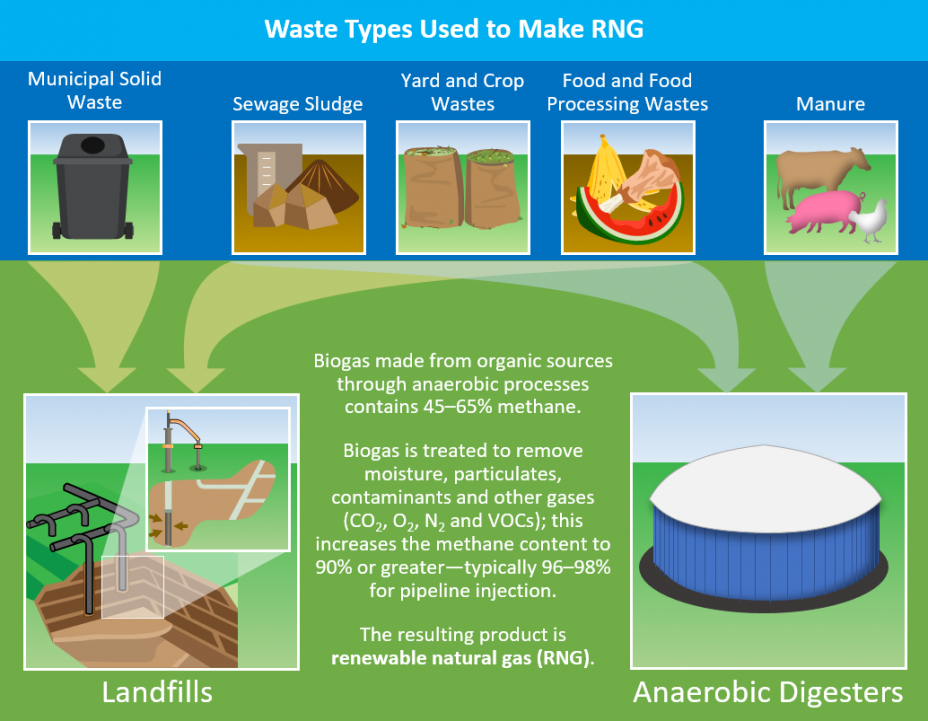

Renewable natural gas (RNG)* is a term used to describe biogas![]() biogasGas resulting from the decomposition of organic matter under anaerobic conditions. The principal constituents are methane and carbon dioxide. that has been upgraded for use in place of fossil natural gas. The biogas used to produce RNG comes from a variety of sources, including municipal solid waste landfills, digesters at water resource recovery facilities (wastewater treatment plants), livestock farms, food production facilities and organic waste management operations.

biogasGas resulting from the decomposition of organic matter under anaerobic conditions. The principal constituents are methane and carbon dioxide. that has been upgraded for use in place of fossil natural gas. The biogas used to produce RNG comes from a variety of sources, including municipal solid waste landfills, digesters at water resource recovery facilities (wastewater treatment plants), livestock farms, food production facilities and organic waste management operations.

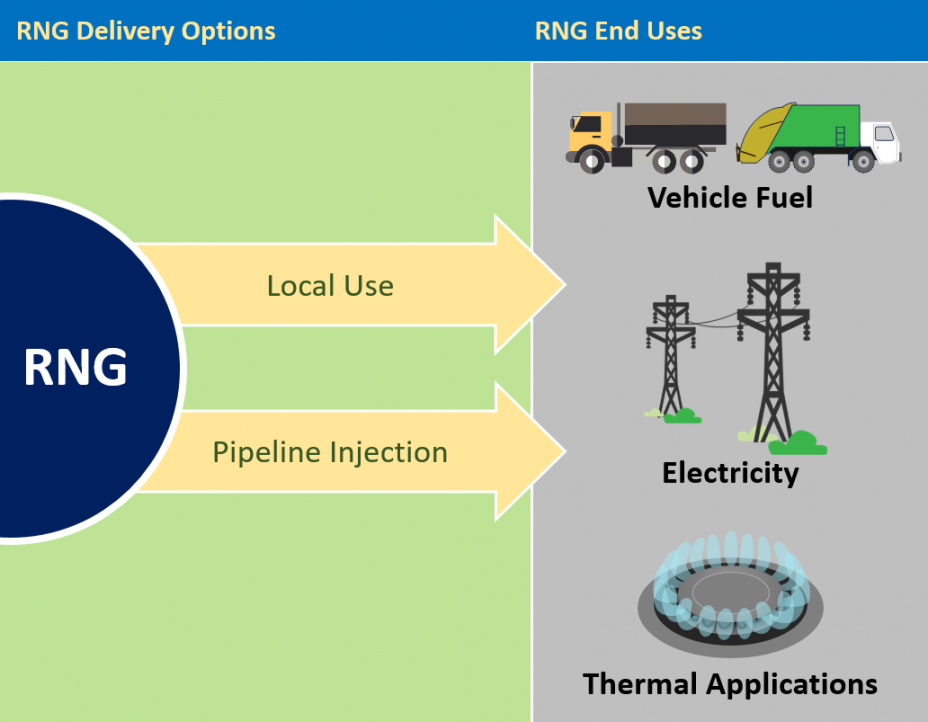

As a substitute for natural gas, RNG has many end uses:

- in thermal applications,

- to generate electricity,

- for vehicle fuel or

- as a bio-product feedstock.

Landfill and Agriculture RNG Projects in the United States (2005-2020)

| Year | Ag RNG Projects | Landfill RNG Projects |

|---|---|---|

| 2005 | 1 | 11 |

| 2006 | 1 | 13 |

| 2007 | 1 | 17 |

| 2008 | 5 | 20 |

| 2009 | 3 | 27 |

| 2010 | 5 | 30 |

| 2011 | 5 | 31 |

| 2012 | 7 | 33 |

| 2013 | 6 | 38 |

| 2014 | 6 | 39 |

| 2015 | 6 | 41 |

| 2016 | 7 | 41 |

| 2017 | 9 | 45 |

| 2018 | 8 | 60 |

| 2019 | 12 | 65 |

| mid-2020 | 19 | 67 |

RNG can be used locally at the site where the gas is created or it can be injected into natural gas transmission or distribution pipelines.

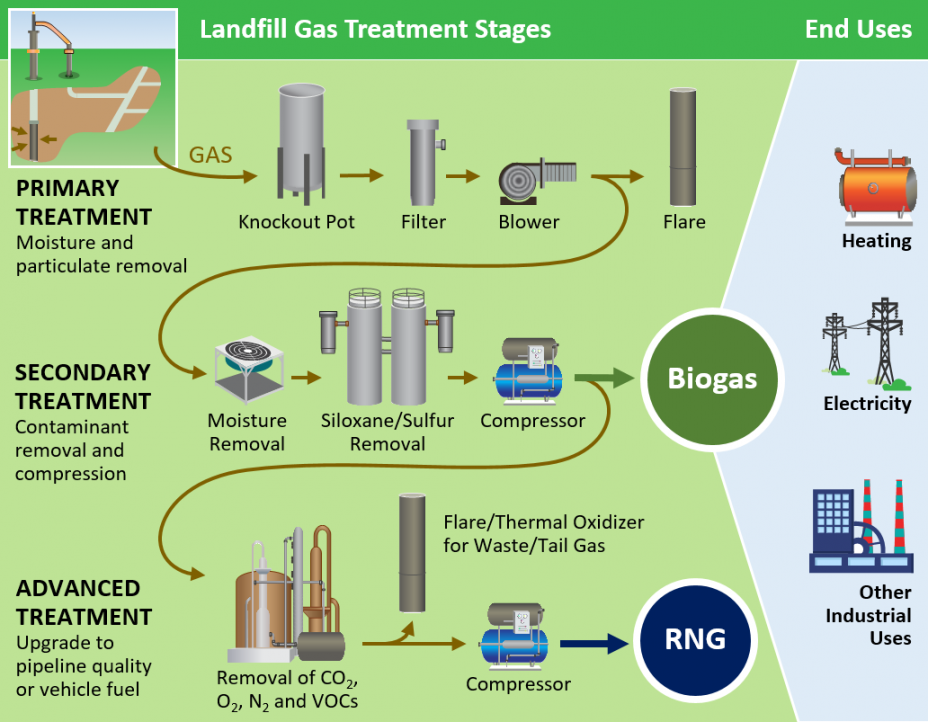

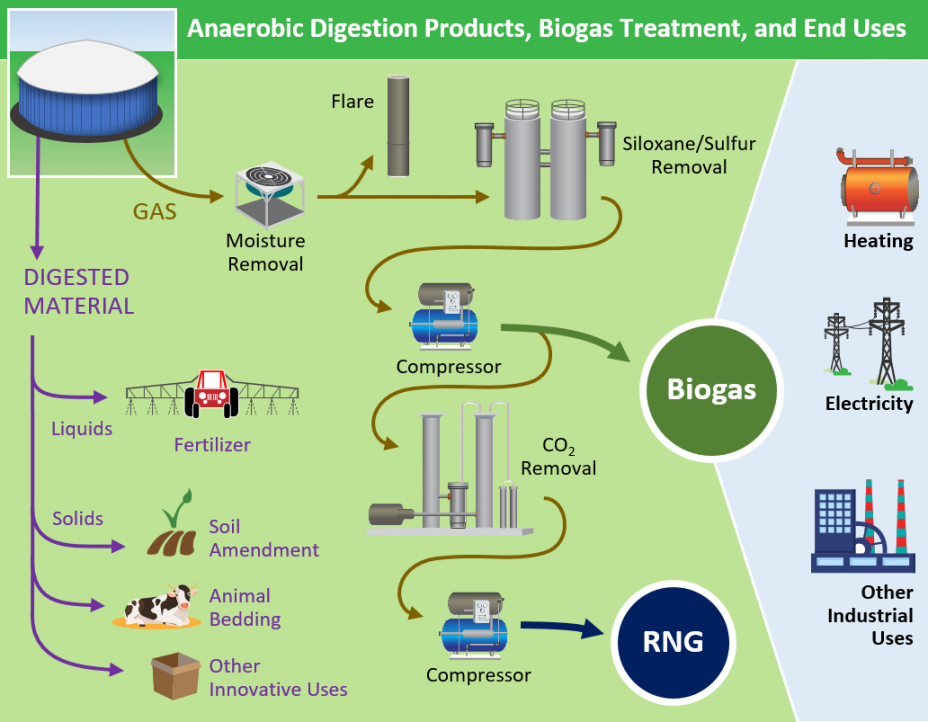

Raw biogas has a methane content between 45 and 65 percent, depending on the source of the feedstock, and must go through a series of steps to be converted into RNG. Treatment includes removing moisture, carbon dioxide (CO2) and trace level contaminants (including siloxanes, volatile organic compounds, or VOCs, and hydrogen sulfide), as well as reducing the nitrogen and oxygen content. Once upgraded, the gas has a methane content of 90 percent or greater. Typically, RNG injected into a natural gas pipeline has a methane content between 96 and 98 percent.

Read more about RNG in EPA’s resource An Overview of Renewable Natural Gas from Biogas.

View and use pertinent biogas-related tools and resources in EPA’s Biogas Toolkit.

*RNG is a “term of art” and there is not at present a standard definition. This description has been developed by EPA’s voluntary programs.

Diagrams of RNG Sources, Gas Treatment and End Uses

Click on a thumbnail image to see the full-sized diagram.

RNG Project Map

Biogas from a variety of sources is being upgraded into RNG across the United States. This map shows operational RNG projects in the United States where the biogas is generated from landfills or livestock waste anaerobic digesters.

Landfill Ag digester

Sources of these data include:

Benefits

Use of RNG can provide benefits in terms of fuel security, economic revenues or savings, local air quality and greenhouse gas emission reductions.

Fuel diversity benefits

Use of RNG increases and diversifies domestic energy production. RNG can be used as a baseload fuel source with high availability rates. It leverages existing infrastructure such as pipelines and heavy-duty vehicles. Biogas feedstocks for RNG are generated continuously from a variety of sources.

Economic benefits

The development of RNG projects can benefit the local economy through the construction of RNG processing and fueling station infrastructure and sale of natural gas-powered vehicles. National, state and local incentives may be available depending on the end use, such as credits for production of RNG used for vehicle fuel. These financial incentives can provide additional economic drivers for project development.

Local air quality benefits

Replacing traditional diesel or gasoline with RNG can significantly reduce emissions of nitrogen oxides and particulate matter, resulting in local air quality benefits. RNG is comprised primarily of methane; compared to fossil natural gas, RNG contains zero to very low levels of constituents, such as ethane, propane, butane, pentane or other trace hydrocarbons.

Greenhouse gas emission reductions

RNG projects capture and recover methane produced at a landfill or anaerobic digestion (AD) facility. Methane has a global warming potential more than 25 times greater than CO2 and a relatively short (12-year) atmospheric life, so reducing these emissions can achieve near-term beneficial impacts in mitigating global climate change. For facilities that are not already required to mitigate such emissions, an RNG project can reduce methane emissions significantly.

Resources

The following EPA resources are available to learn more about RNG:

• Renewable Natural Gas from Landfill Gas and Sustainability at L’Oréal

• Renewable Natural Gas from Landfill Gas and Sustainability at L’Oréal• Franklin County Landfill Gas to Pipeline Renewable Natural Gas Energy Project

• Wellfield Operations and Technologies for Upgrading Landfill Gas

• Upgrading Landfill Gas for Pipeline Gas and Vehicle Fuel

• 2019 Renewable Natural Gas Workshop

• 2019 Renewable Natural Gas Workshop• 2018 Natural Gas STAR and Methane Challenge Renewable Natural Gas Workshop

• Renewable Natural Gas: Driving Value for the Natural Gas and Biogas Sectors

• 2019 RNG Resources and Insights from EPA Partnership Programs

• 2019 RNG Resources and Insights from EPA Partnership Programs(LMOP Presentation)

• RNG Projects in the Agricultural Sector

(AgSTAR Webinar)

More Information on RNG

The following EPA programs work cooperatively with industry stakeholders to reduce or avoid methane emissions by supporting biogas energy projects including those that produce RNG.

EPA’s Landfill Methane Outreach Program (LMOP) encourages the recovery and beneficial use of biogas generated from organic municipal solid waste. LMOP maintains a database that includes operational RNG projects as well as opportunities for landfill sites where RNG could potentially be generated. In addition, LMOP publishes tools and resources to support the development of RNG projects.

EPA’s AgSTAR promotes the use of biogas recovery systems to reduce methane emissions from livestock waste. AgSTAR provides a wide variety of resources and tools for stakeholders interested in exploring the use of AD systems and maintains a list of projects with information on the AD feedstock sources and end use of the biogas. See more information from AgSTAR about RNG from Agricultural-Based AD and Biogas Systems.

EPA’s AgSTAR promotes the use of biogas recovery systems to reduce methane emissions from livestock waste. AgSTAR provides a wide variety of resources and tools for stakeholders interested in exploring the use of AD systems and maintains a list of projects with information on the AD feedstock sources and end use of the biogas. See more information from AgSTAR about RNG from Agricultural-Based AD and Biogas Systems.

EPA’s Natural Gas STAR programs encourage oil and natural gas companies to adopt cost-effective technologies and processes that improve operational efficiencies and reduce methane emissions. The program also facilitates technology transfer between stakeholders to discuss technical questions regarding the injection of RNG into the natural gas pipeline network.

EPA’s Natural Gas STAR programs encourage oil and natural gas companies to adopt cost-effective technologies and processes that improve operational efficiencies and reduce methane emissions. The program also facilitates technology transfer between stakeholders to discuss technical questions regarding the injection of RNG into the natural gas pipeline network.

EPA’s Green Power Partnership is a voluntary program that encourages organizations to use green power as a way to reduce the environmental impacts associated with conventional electricity use.

EPA’s Green Power Partnership is a voluntary program that encourages organizations to use green power as a way to reduce the environmental impacts associated with conventional electricity use.

The Renewable Fuel Standard Program (RFS) is run by the EPA Office of Transportation and Air Quality. Learn more about the RFS.