Bayer Crop Science Facility - 2018 P2 Awardee

Kansas City, Missouri

Awardees with EPA Region 7 Administrator Jim Gulliford (click to enlarge)Bayer’s Crop Science Division is an agriculture enterprise with businesses in crop protection, seeds, and pest control. The Kansas City facility includes pesticide active ingredient manufacturing, along with formulation and packaging operations.

Awardees with EPA Region 7 Administrator Jim Gulliford (click to enlarge)Bayer’s Crop Science Division is an agriculture enterprise with businesses in crop protection, seeds, and pest control. The Kansas City facility includes pesticide active ingredient manufacturing, along with formulation and packaging operations.

Bayer’s pollution prevention efforts from 2015 to 2017 focused on reducing wastewater generated from the washout of equipment used to formulate and package products. During a typical year, approximately 115 different products and 60 to 70 million pounds of products will be packaged. To prevent cross-contamination, the equipment must be cleaned between product runs. That cleaning uses a significant amount of water and generates wastewater that requires treatment or other management. Using 2014 as a baseline, 12.9 million pounds (1.54 million gallons) of water were used for washouts and an equivalent amount of wastewater was generated.

The following is a list of improvements made during the 2015-2017 time frame:

The following is a list of improvements made during the 2015-2017 time frame:

- Improved production scheduling, such as sequencing similar products together, decreased the amount of wash water required. (For example, a red product following a red product, rather than a white product following a red product.)

- Rerouted wash water directly to plant sumps to eliminate the wasteful practice of washing the floors.

- Converted a formulation plant from producing multiple products to a single product, which resulted in fewer washouts and less wastewater generation.

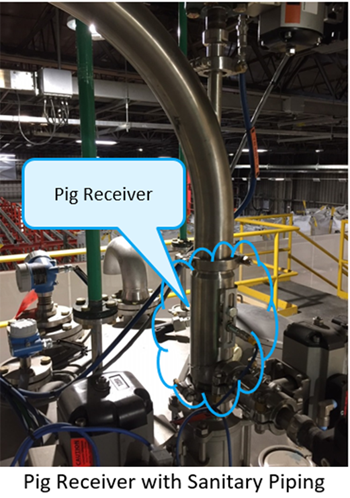

- Installed new pipelines constructed of sanitary tubing and installed polished tanks to reduce the amount of wastewater produced.

- Installed new pigging technology, which requires significantly less water to clean the pipelines compared to regular washout practices.

- Installed and used spray nozzles to improve washing efficiency. This allowed most of the batch water to be added through the spray nozzles, which keeps the tank walls clean and thereby requires less washing at the end of a product run.

- Installed a filter cleaner in one of the plants, reducing the amount of water needed during washout.

Additional benefits realized from these efforts include:

- Personnel exposure to the hazards in the wastewater decreased during the washout process due to the reduced washout frequency, use of pigging technology, and use of spray nozzle technology.

- Less personnel resources and time are needed to complete washouts.

- Increased on-site incinerator capacity, cost-effectiveness, and potential for adding new products into production.

- Decreased waste shipping for off-site treatment.

With 2014 as the baseline, there were 102 fewer washouts (27-percent reduction) in 2017 and the amount of wastewater generated was 3.2 million pounds (382,000 gallons) or 25 percent less in 2017. These improvements were accomplished while the quantity of products packaged increased by 14 percent in 2017, compared to 2014. Normalized to amount of goods packaged, the amount of wastewater generated was reduced by 34 percent. The reduced wastewater consumption saved Bayer $2.4 million at an average treatment cost of $0.30 per pound of wastewater treated during the three-year period.

Bayer’s efforts could serve as a model for others in several ways. These efforts embody the spirit of continuous improvement and it’s not about simply implementing one big change to reduce the amount of wastewater generated. Rather, it has required multiple projects and many individuals who added their own small but significant contributions. As such, these efforts demonstrate the benefits of implementing the Plan-Do-Check-Act (PDCA) cycle for carrying out change and can serve as a model to other organizations looking to address environmental challenges through a continuous improvement effort.

Another lesson to share is the power of measuring. Wastewater was a very significant part of the overall product cost. Until Bayer started measuring the amount of wastewater being generated, the facility did not have an appreciation of the true impact on the product cost. By measuring the amount of wastewater generated and establishing other key performance indicators, the facility also started tracking and seeing the results of the improvement efforts. This feedback of positive results in turn further fueled employees’ desire to make additional improvements.

Finally, Bayer learned the importance and benefits of considering and acting upon wastewater reduction efforts during the design phase of new projects. Addressing the conservation of water during washouts during the design of new formulation and packaging systems was found to be significantly more efficient than efforts to reduce wastewater generation after a system or operation had already been built and placed in operation. This concept is readily transferrable to other pollution prevention and conservation efforts.