Stories of Progress in Achieving Healthy Waters

U.S. EPA Region 3 Water Protection Division

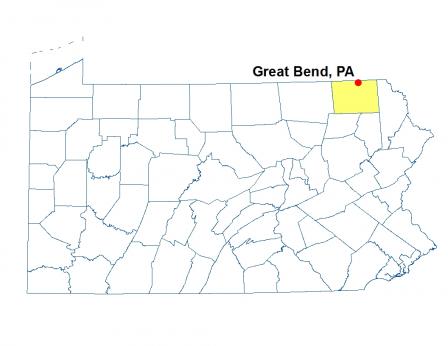

Great Bend, Pennsylvania • January 29, 2015

With EPA and state assistance, sewer authority achieving energy savings and pollution reductions by optimizing its wastewater treatment plant processes.

The Hallstead Great Bend Joint Sewer Authority recently upgraded its wastewater treatment plant (WWTP) to meet Chesapeake Bay nutrient limits, dynamically changing the efficiency of the process. The complex plant had overwhelmed the Authority and its two WWTP operators until teams from EPA and the Pennsylvania Department of Environmental Protection (PADEP) provided assistance.

PADEP Operator Outreach Exit and Enforcement teams met with the Authority board members, engineer and operators to discuss the type of lab equipment, maintenance, and staffing needed to achieve compliance and avoid significant fines.

The Authority worked with PADEP, the EPA Mid-Atlantic Region Energy/Optimization team, and its engineers and contractor to resolve significant operational and construction problems. For example, poor construction of the chemical phosphorus removal system led to multiple events where the sand filter clogged, creating compliance issues with the phosphorus limit. After months of operational issues, the superintendent identified the culprit – the contractor had installed the chemical feed to the WRONG process!

The EPA Region 3 Energy/Optimization team focused on process control training and energy efficiency. General process control outreach was conducted on site, over telephone and email.

One recent success resulted when the EPA team recommended that the superintendent change the aeration timing of the sludge digesters to operate intermittently as opposed to 24 hours per day, reducing the level of Nitrate-Nitrogen (NO3) discharged back into the main process (from 82.6mg/l NO3 to 0.18mg/l NO3) and saving a significant amount of energy. The approximate savings in energy is 54,000 kilowatt hours/yr ($4,300/yr). The Authority is motivated by the potential energy savings and is currently working with the EPA team on other optimization and energy efficiency projects.

In December 2014, the Authority was approached by the Pennsylvania Rural Water Association (PRWA) to write an article about its successes in the association’s quarterly, state-wide magazine, the Keystone Tap Exit.

-

EPA PADEP Help Sewer Authority Reduce Pollutants, Save Energy (PDF)(1 pg, 700 K,

01/29/2015)

With EPA and state assistance, sewer authority achieving energy savings and pollution reductions by optimizing its wastewater treatment plant processes