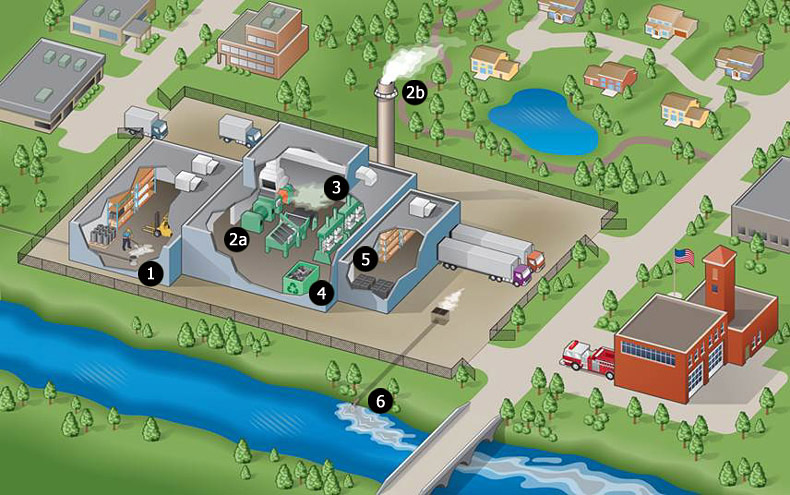

This graphic shows a sample (fictional) facility that manufactures rubber products. For selected industrial processes at the facility, you can learn about how and where three TRI-reported chemicals are used, managed, and released into the environment, and how they're reported on the TRI reporting form.

Click on any of the numbers in the graphic to get started.

Raw Material Storage

This facility keeps the raw materials used to make rubber products in a storage room. These raw materials include zinc compounds, lead compounds and oils containing PACs, materials used to improve the chemical characteristics of the rubber products. Chemicals are sometimes spilled when materials are transferred from the storage room for use in a process at the facility. For example, opening a bag that stores zinc compounds can cause dust containing the zinc compounds to enter the air and then settle onto the floor. To clean spills, the floors are mopped and wastewater containing the zinc compound dust is washed down a drain that feeds into a pipe leading to a POTW (a waste water treatment facility). TRI facilities report this as a transfer to a POTW.

Note that water discharges from this facility are routed to two different locations: wastewater collected in indoor drains flows to a POTW where it’s treated prior to release into the environment, while stormwater collected in drains in the parking lot flows directly to surface waters (see #6).

Previous - Next

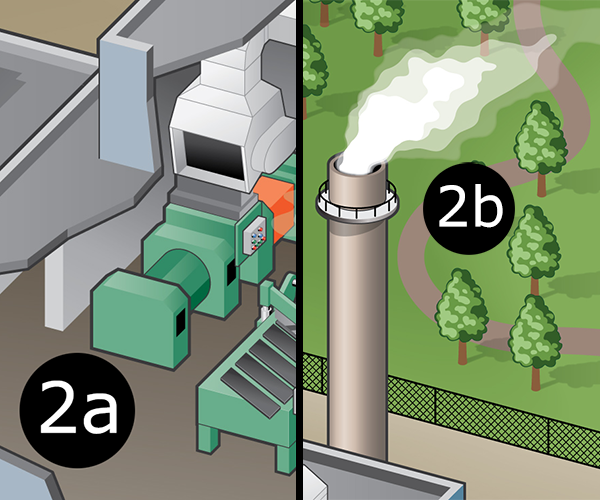

Mixing

This facility combines raw materials (rubber, oils, and chemical additives) in large mixers under high heat and pressure (2a). Zinc compounds, lead, and oils containing PACs are added to change the chemical characteristics of the rubber. Gases containing these chemicals are produced during mixing. These gases are collected in a fume hood above the mixer, then routed through a pollution control device designed to capture the chemicals and prevent their release to the environment. Gases that are not successfully captured by the device are released to the air outside the facility through a smokestack (2b). TRI facilities report this as a stack air release.

Previous - Next

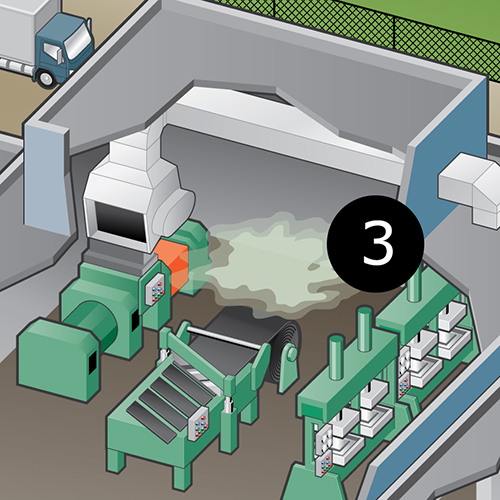

Cutting

This facility cuts large sheets of rubber into smaller pieces that can be molded into rubber products. As the rubber is cut, tiny particles containing PACs enter the air inside the facility. Air carrying these particles then flows outside of the facility through doors and windows, and the PACs are released into the environment. TRI facilities report this as a fugitive air release.

Previous - Next

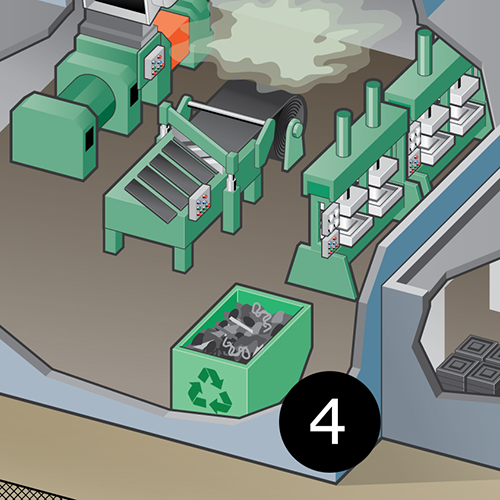

Curing

This facility cures rubber under heat and pressure in molds. Curing gives rubber products their final shape and changes the chemical composition of the rubber to make it elastic. After curing, any off-spec rubber products, including those containing lead compounds, zinc compounds and PACs, are transferred off-site to a waste management company for recycling. TRI facilities report this as an off-site transfer.

Previous - Next

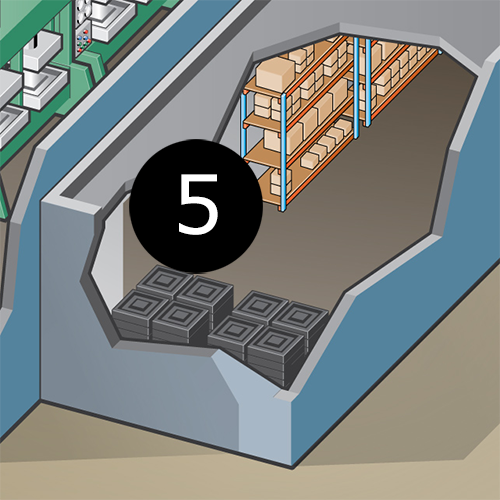

Product Storage

This facility packages and ships finished rubber products for sale to consumers. The rubber in these products still contains lead compounds, zinc compounds and PACs, but the quantities of chemicals contained in these products are not reported to TRI. TRI does not contain information on the quantities of chemicals contained in products that are sold to consumers.

Previous - Next

Storm Drain

At this facility, lead compounds, zinc compounds, and PACs sometimes spill onto the ground as raw materials are unloaded from delivery trucks and as wastes are loaded onto trucks. Rain washing over these spills carries the chemicals into storm drains and through pipes that discharge them into a local waterbody (e.g., a river). TRI facilities report this as a surface water discharge.

Note that water discharges from this facility are routed to two different locations: wastewater collected in indoor drains flows to a POTW where it is treated prior to being released into the environment (see #1), while stormwater collected in drains in the parking lot flows directly into surface waters.

Previous - Next

The diagram shown above illustrates an example of a facility that meets TRI reporting requirements, including how and where TRI chemicals are used at the facility. The diagram is not intended to represent exactly what happens at every TRI facility, as chemicals and processes vary across facilities and industry sectors.

Please note that definitions of TRI terms on this webpage have been simplified for educational purposes and should not be relied upon to determine your facility’s TRI reporting obligations. See the Reporting Forms and Instructions document for extensive reporting guidance.

Finally, please also note that this diagram only encompasses information that relates to TRI reporting and doesn’t reflect if or how this facility is regulated by other EPA programs.