AgSTAR's Market Opportunities for Biogas Recovery Systems at U.S. Livestock Facilities report assesses the market potential for biogas energy projects at swine and dairy farms in the United States, including details on the methodology and sample calculations. For the top ten swine and dairy states, the guide characterizes the sizes and types of operations where biogas projects are technically feasible, along with estimates of potential methane production, electricity generation and greenhouse gas emission reductions.

AgSTAR's Market Opportunities for Biogas Recovery Systems at U.S. Livestock Facilities report assesses the market potential for biogas energy projects at swine and dairy farms in the United States, including details on the methodology and sample calculations. For the top ten swine and dairy states, the guide characterizes the sizes and types of operations where biogas projects are technically feasible, along with estimates of potential methane production, electricity generation and greenhouse gas emission reductions.

Biogas can be collected from manure and burned to meet on-farm energy needs such as electricity, heating, and cooling. Surplus electricity or biogas can also be sold to neighboring operations or the utility grid. As of August 2017, AgSTAR estimates, 250 manure anaerobic digester biogas recovery systems were in operation at commercial livestock facilities in the United States. The full potential to provide renewable energy is much greater: an estimated 8,100 U.S. dairy and swine operations could support biogas recovery systems. These systems may also be feasible at some poultry and beef lot operations as new and improved technologies for these manure types enter the market.

Potential for Biogas Recovery Systems at U.S. Swine and Dairy Operations

| Animal Sector | Candidate Farms | Energy Generating Potential | ||

|---|---|---|---|---|

| MW | MWh/year | Thousands of MMBtu/year | ||

| Swine | 5,409 | 837 | 6,597,520 | 71,484 |

| Dairy | 2,704 | 1,172 | 9,240,893 | 100,124 |

| Total | 8,113 | 2,009 | 15,838,413 | 171,608 |

Candidate farms for biogas recovery systems were identified using the characteristics described in the table below. These characteristics were chosen based on AgSTAR evaluations of the technical and economic performance of successful digester systems operating on commercial-scale swine and dairy farms. Appendix A of the report offers details on the methodology for identifying candidate farms and estimating their energy production potential.

Typical Characteristics for Profitable Biogas Recovery Systems

| Animal Type | Manure Management Method1 | Size of Operation |

|---|---|---|

| Dairy | Flushed or scraped freestall barns and open lots | ≥ 500 head |

| Swine | Houses with flush, pit recharge, or pull-plug pit systems2 | ≥ 2,000 head |

1Assuming total solids content below 15 percent and at least weekly manure collection.

2Swine confinement houses in cool regions, such as the upper Midwest, commonly use deep pits under slatted floors. Biogas systems are not currently used with deep pits, which would need to be modified to remove manure more often before biogas capture and use systems could be installed. The feasibility of conversion depends on the value of the biogas produced relative to the capital investment required. Estimates in this report assume that deep pit operations with more than 5,000 head could use biogas systems by converting to at least weekly manure removal.

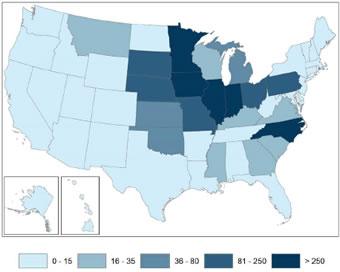

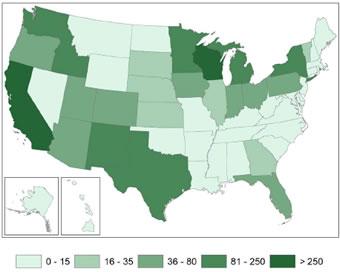

The number of dairy and swine farms with the potential to recover methane varies significantly from state to state. The figures below depict the number of candidate swine and dairy farms in each state, respectively. Appendix B of the report offers more detail on the market potential in the swine and dairy states with the greatest potential for biogas recovery.

Candidate Swine Farms

Candidate Swine Farms Candidate Dairy Farms

Candidate Dairy Farms-

Market Opportunities for Biogas Recovery Systems at U.S. Livestock Facilities (PDF)(42 pp, 12 MB,

June 2018,

430-R-18-006)

This document updates AgSTAR’s 2011 Market Opportunities for Biogas Recovery Systems at U.S. Livestock Facilities. It includes updates to USDA data and minor revisions to calculation methodologies or default factors used in calculations. Methane’s global warming potential (GWP), which is used to estimate emission reductions, was updated from 21 to 25 times the heat trapping capacity of carbon dioxide (CO2) to be consistent with the IPCC Fourth Assessment Report: Climate Change 2007 (AR4).