Coil Coating Effluent Guidelines

EPA promulgated the Coil Coating Effluent Guidelines and Standards (40 CFR Part 465) in 1982 and amended the regulation in 1983. The regulation covers direct and indirect dischargers. The Effluent Guidelines and Standards are incorporated into NPDES permits for direct dischargers

EPA promulgated the Coil Coating Effluent Guidelines and Standards (40 CFR Part 465) in 1982 and amended the regulation in 1983. The regulation covers direct and indirect dischargers. The Effluent Guidelines and Standards are incorporated into NPDES permits for direct dischargers![]() direct dischargerA point source that discharges pollutants to waters of the United States, such as streams, lakes, or oceans., and permits or other control mechanisms for indirect dischargers

direct dischargerA point source that discharges pollutants to waters of the United States, such as streams, lakes, or oceans., and permits or other control mechanisms for indirect dischargers![]() indirect dischargerA facility that discharges pollutants to a publicly owned treatment works (municipal sewage treatment plant). (see Pretreatment Program).

indirect dischargerA facility that discharges pollutants to a publicly owned treatment works (municipal sewage treatment plant). (see Pretreatment Program).

- What is the Coil Coating Industry?

- Canmaking

- Facilities Covered

- Related Categories

- Guidance Document

- Rulemaking History

- Additional Information

What is the Coil Coating Industry?

Coil coating is a term generally used to describe the combination of processing steps involved in converting a coil--a long thin strip of metal rolled into a coil--into a coil of painted metal ready for further industrial use. Three basis materials are commonly used for coil coating: steel, galvanized steel, and aluminum. Additionally, there is some minor coating of other materials such as brass, galvalum (a zinc-aluminum alloy) and coated steels. There are three major groups or standard process steps used in manufacturing coated coils:

- Cleaning to remove soil, oil, corrosion, and similar dirt

- Chemical conversion coating, in which a coating of chromate, phosphate or complex oxide materials is chemically formed in the surface of the metal

- Application and drying polymeric material, such as paint.

Water Use

Water is used throughout the coil coating processes. The cleaning processes for removing oil and dirt usually employ water-based alkaline cleaners, and acid pickling solutions are sometimes used to remove oxides and corrosion. Water is used to rinse the strip after it has been cleaned. Most of the chemical conversion coating processes are water based and water is used to rinse excess and spent solutions from the strip. After painting, the strip is baked in an oven to dry the paint and then chilled with water to prevent burning or charring of the organic coating. The characteristics of the wastewater generated by coil coating may vary depending on the basis material and the process options selected for cleaning and chemical conversion coating.

Significant Pollutants

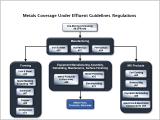

- Toxic pollutants: chromium, zinc, nickel, lead, copper, cyanide

- Conventional pollutants: suspended solids, pH (abnormally high or low), and oil and grease

- Unconventional pollutants: iron, aluminum, phosphorous, and fluoride.

Because of the amount of toxic metals present, the sludges generated during wastewater treatment generally contain substantial amounts of toxic metals.

At the time of the 1982 rulemaking there were approximately 75 coil coating facilities in the United States, operating over 125 coil coating lines.

Canmaking

The Canmaking Subcategory was added to the regulation in a 1983 amendment. Canmaking covers all of the manufacturing processes and steps involved in the manufacturing of shaped metal containers which are subsequently used for storing foods, beverages and other products. Two major types of cans are manufactured: seamed cans and seamless cans. Seamed cans (primarily three-piece cans) are manufactured by forming a flat piece or sheet of metal into a container with a longitudinal or side seam which is clinched, welded, or soldered, and attaching formed ends to one or both ends of the container body. At the time of the 1983 rulemaking about 300 plants in the United States manufactured seamed cans.

Seamless cans consist of a can body formed from a single piece of metal and usually a top, or two ends, that are formed from sheet metal and attached to the can body. there are several forming methods which may be used to shape the can bodies including simple drawing, drawing and redrawing, drawing and ironing (D&I), extruding, spinning, and others. About 125 plants in the United States manufactured seamless cans in 1983.

In the manufacture of seamless cans, oil is used frequently as a lubricant during the forming of the seamless body and must be removed before further processing can be performed. Typically, this is accomplished by washing the can body in a continuous can washer using water based alkaline cleaners. This step is followed by metal surfacing steps to prepare the can for painting.

Significant Pollutants

- Toxic metals: chromium and zinc

- Toxic organics; listed as total toxic organics (TTO)

- Nonconventional pollutants: aluminum, fluoride, and phosphorous

- Conventional pollutants: oil and grease, TSS, and pH (abnormally high or low).

Because of the toxic metals present, the sludges generated during wastewater treatment generally contain toxic metals.

At the time of the 1983 rulemaking, 88 of the approximately 425 can manufacturing plants in the United States discharged wastewater.

Excluded from the Canmaking Subcategory: Manufacture of seamed cans, can ends, can tops and seamless cans from coated (e.g., coil coated) stock. No oil is used in this process and the cans do not need to be washed after forming.

Classification

-

332431: Metal Can Manufacturing

-

332812: Metal Coating, Engraving (except Jewelry and Silverware), and Allied Services to Manufacturers

Note: The NAICS listing is provided as a guide and does not define the coverage of the Coil Coating category. For precise definitions of coverage, see the Applicability sections in 40 CFR Part 465.

Facilities Covered

-

Steel

-

Galvanized (zinc-coated steel, galvalum, brass and other copper-base strip)

-

Aluminum (including aluminum alloys and aluminum-coated steel)

Subpart D covers canmaking operations.

Related Categories

- Aluminum Forming (40 CFR Part 467)

- Iron and Steel Manufacturing (40 CFR Part 420)

- Metal Finishing (40 CFR Part 433)

Guidance Document

Rulemaking History

1983 Amendment

- Documents, including:

- Final Rule (November 17, 1983)

- Development Document (Canmaking Subcategory – April 1984)

Industry description, wastewater characterization, treatment technologies, regulatory compliance cost estimates and pollutant loadings for the final rule - Proposed Rule (February 10, 1983)

1982 initial Rulemaking

-

Documents, including:

-

Final Rule (December 1, 1982)

-

Development Document (November 1982)

-

Industry description, wastewater characterization, treatment technologies, regulatory compliance cost estimates and pollutant loadings for the final rule

-

Proposed Rule (January 12, 1981)

-

Additional Information

For additional information regarding Coil Coating Effluent Guidelines, please contact Jezebele Alicea (alicea.jezebele@epa.gov) or call 202-566-1755.