Copper Forming Effluent Guidelines

EPA promulgated the Copper Forming Effluent Guidelines and Standards (40 CFR Part 468) in 1983 and amended the regulation in 1986. The regulation covers direct

EPA promulgated the Copper Forming Effluent Guidelines and Standards (40 CFR Part 468) in 1983 and amended the regulation in 1986. The regulation covers direct![]() direct dischargerA point source that discharges pollutants to waters of the United States, such as streams, lakes, or oceans. and indirect

direct dischargerA point source that discharges pollutants to waters of the United States, such as streams, lakes, or oceans. and indirect![]() indirect dischargerA facility that discharges pollutants to a publicly owned treatment works (municipal sewage treatment plant). dischargers. The Effluent Guidelines and Standards are incorporated into NPDES permits for direct dischargers, and permits or other control mechanisms for indirect dischargers (see Pretreatment Program).

indirect dischargerA facility that discharges pollutants to a publicly owned treatment works (municipal sewage treatment plant). dischargers. The Effluent Guidelines and Standards are incorporated into NPDES permits for direct dischargers, and permits or other control mechanisms for indirect dischargers (see Pretreatment Program).

What is the Copper Forming Industry?

Copper forming plants roll, draw, extrude, and forge copper and copper alloys. In addition to these forming operations, there are surface cleaning and heat treatment processes which impart desired surface and physical properties to the metal.

For the purposes of this regulation, copper alloys include any alloy in which copper is the major constituent. Principal alloys processed by copper formers include brass, bronze, leaded brass, leaded bronze, nickel silvers, phosphor bronze, aluminum bronze, silicon bronze, beryllium copper, and cupronickel.

At the time of the 1983 rulemaking there were approximately 176 copper forming facilities in the United States.

Products

- Plate is a wide rigid piece of metal usually greater than ¼ inch thick. Printing plates were often made from copper, as are plate heat exchangers and some chemical processing vessels.

- Sheet is a wide piece of metal having little rigidity and usually less than ¼ inch thick.

- With strip, the length is many times the width and the product is commonly handled as coils of metal called coiled strip. Its uses include roof gutters, gaskets, radio parts, trim, weather strip, washers, diaphragms, etc.

- Wire is usually circular in cross section and is flexible. Wire that is twisted or woven into strands, used for lifting or in structural supports, is known as cable.

- Rod is similar to wire in that it has a circular cross section but is more rigid. Rod and wire are used for screening, fasteners, jewelry, cotter pins, lock washers, springs, truss wire, wire brushes, welding rods, chains, hooks, and electrical conductors.

- Tubing is material in the form of long hollow cylinders. In general, tubing is used for transporting fluids and heat transfer applications. Specifically, it is used for gas lines; heater lines; oil burner tubes; plumbing pipe and tube; refrigerators; condensers; evaporators; heat-exchanger tubes; dairy tubes, and hydraulic lines.

- Forgings are formed from copper, usually hot, by individual and intermittent applications of pressure. Forging may be done in open or closed dies. These pieces generally have more intricate shapes than other types of formed copper products.

- 331421: Copper Rolling, Drawing, and Extruding

- 331422: Copper Wire (except Mechanical) Drawing

Note: the NAICS listing is provided as a guide and does not define the coverage of the Copper Forming category. For precise definitions of coverage, see the applicability sections in 40 CFR Part 468.

Manufacturing Techniques

- Hot rolling

- Cold rolling

- Extrusion

- Drawing

- Forging

- Surface and heat treatment processes:

- Annealing

- Pickling

- Alkaline cleaning

- Solution heat treatment (quenching)

- Additional operations at some plants:

- Tumbling or burnishing

- Surface coating

- Hydrostatic testing

- Sawing

- Surface milling

Wastestreams

- Lubricants used in the forming processes

- Solution heat treatment (cooling water)

- Alkaline cleaning bath and rinse

- Annealing (cooling water)

- Pickling bath and rinse

- Pickling fume scrubber

- Tumbling or burnishing (lubricant)

- Surface coating

- Miscellaneous

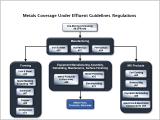

Significant pollutants

- chromium

- copper

- lead

- nickel

- zinc

- toxic organic compounds

- suspended solids

- pH (abnormally high or low)

- oil and grease

Facilities Covered

- Manufacture of formed copper and copper alloy products

- Excluded:

- Forming of beryllium copper alloys (any copper alloy that is alloyed to contain 0.10 percent or greater beryllium)

- Forming of precious metals (any alloy containing 30 or greater percent by weight of precious metals is considered a precious metal)

- Casting of copper and copper alloys

- Copper powders

Related Categories

- Casting is regulated under the Metal Molding and Casting (Foundries) Category (40 CFR Part 464).

- The manufacture of copper powders and the forming of parts from copper or copper alloy powders is regulated under the Nonferrous Metals Forming and Metal Powders Category (40 CFR Part 471).

- Metal Finishing (40 CFR Part 433)

- Metal Products and Machinery (40 CFR Part 438)

Guidance Documents

- Aluminum, Copper, and Nonferrous Metals Forming and Metal Powders Pretreatment Standards: A Guidance Manual (December 1989)

Guidance to publicly owned treatment works (POTWs) on the implementation and enforcement of categorical pretreatment standards - Guidance Manual for Implementing Total Toxic Organics (TTO) Pretreatment Standards (September 1985)

Rulemaking History

1986 Amendment

-

Final Rule (March 5, 1986)

1983 Initial Rulemaking

- Documents, including:

- Final Rule (August 15, 1983)

- Development Document (March 1984)

Industry description, wastewater characterization, treatment technologies, regulatory compliance cost estimates and pollutant loadings for the final rule - Proposed Rule (November 12, 1982)

Additional Information

For additional information regarding Copper Forming Effluent Guidelines, please contact Samantha Lewis (lewis.samantha@epa.gov) or 202-566-1058.